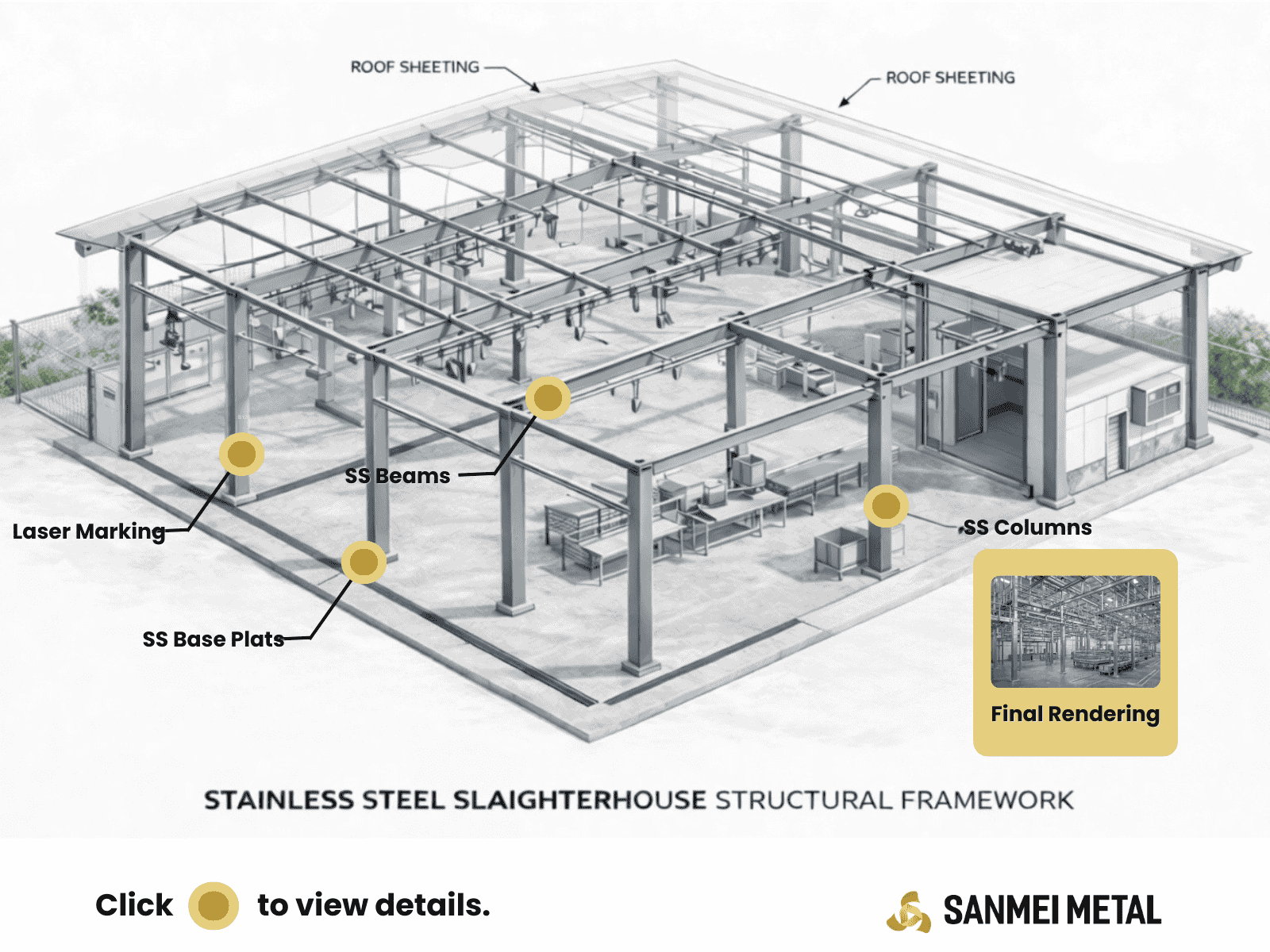

이라크 도축장 시설용 스테인리스강 하중 지지 구조물

This project involves a 304 stainless steel weighing structure designed for slaughterhouse environments with high humidity and strict hygiene requirements.

The entire system is fabricated from stainless steel square tubes.

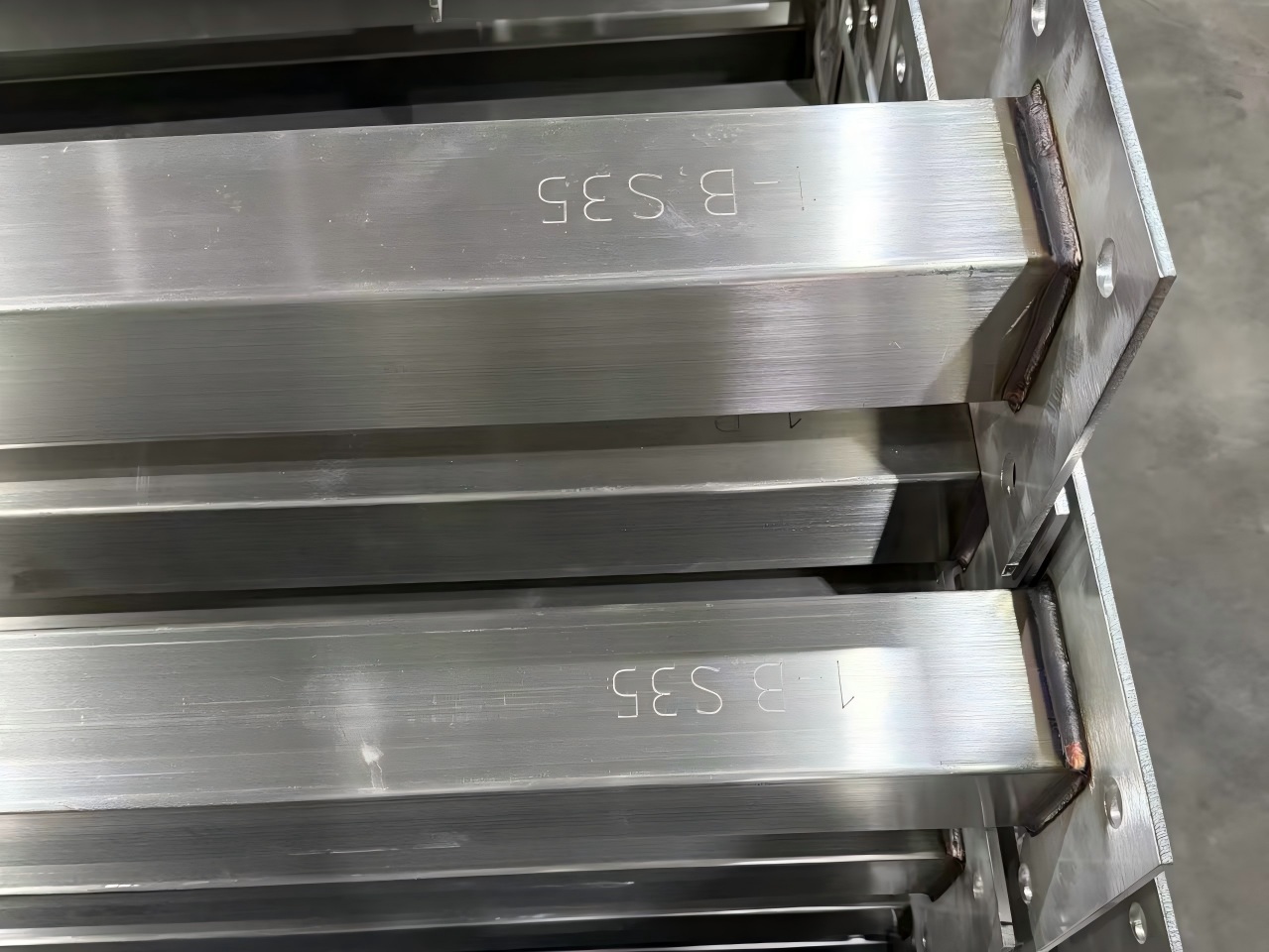

For easier on-site identification and installation, laser-marked numbering is applied to all major structural components.

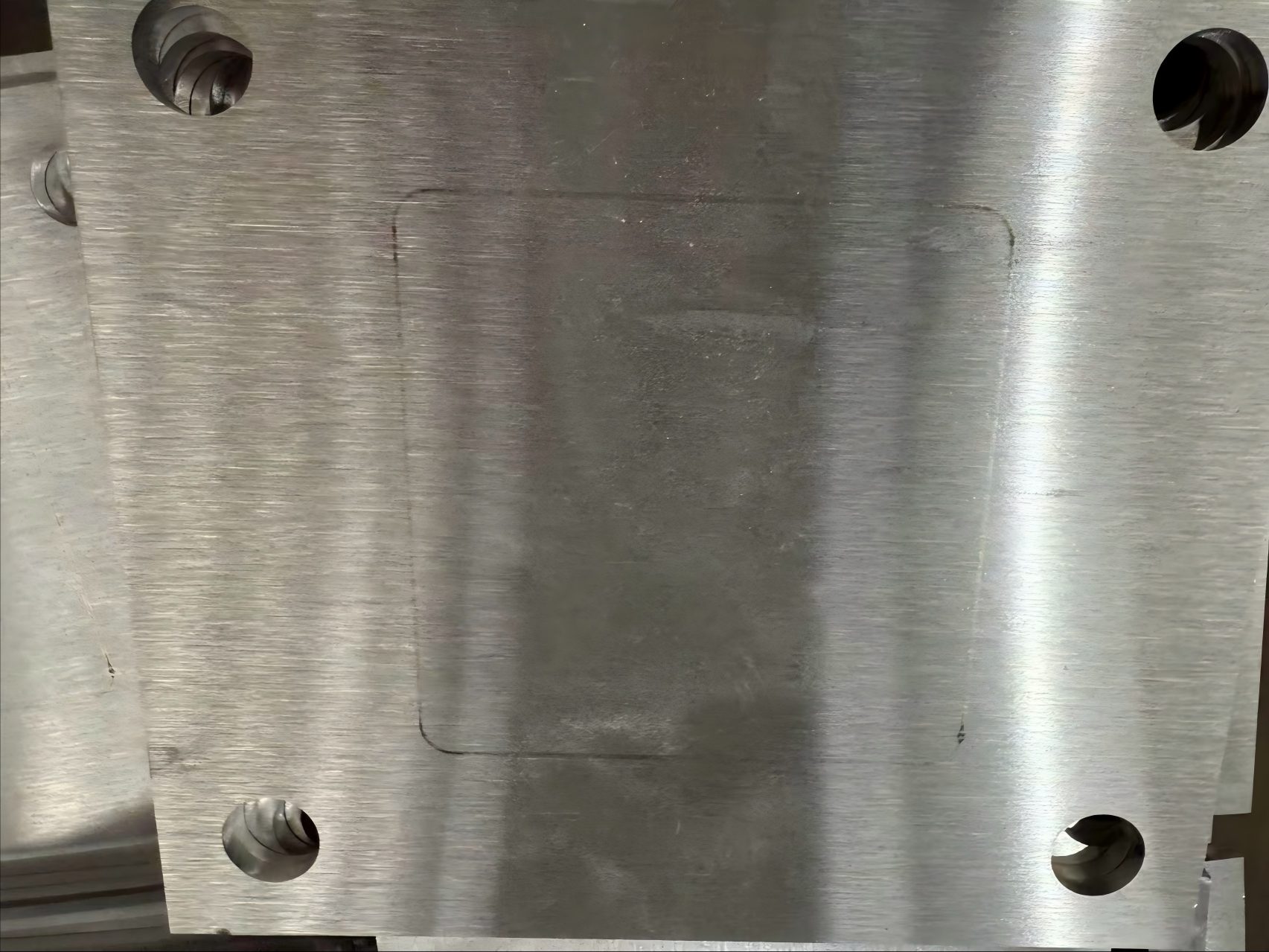

Stainless Steel Base Plates

All base plates are perforated in advance, with hole positions reserved for accurate and efficient on-site installation.

Stainless Steel Columns

The columns are fabricated from square tubes formed from 304 stainless steel plates.

A stainless steel base plate is welded at the bottom of each column, with pre-drilled holes reserved for installation and anchoring.

Stainless Steel Beams

The beams are also made from 304 stainless steel square tubes.

Unlike the columns, stainless steel plates are welded both at the top and bottom of each beam to facilitate structural connection and installation.

All connection plates are pre-drilled according to the project drawings.

Laser Marking

Laser marking is used to permanently identify each major component, improving installation accuracy and long-term traceability.

Final Rendering

프로젝트 개요

This project involved the delivery of a stainless steel load-bearing structure system for a slaughterhouse facility located in Iraq.

Given the nature of slaughterhouse operations—long-term exposure to high humidity, frequent wash-downs, chemical cleaning agents, and strict hygiene regulations—the project presented higher-than-average demands on both corrosion resistance 그리고 structural reliability.

From the early stage, it was clear that material choice alone would not be sufficient. The project required a fabrication partner capable of validating structural logic, executing precision fabrication, and coordinating inspection under industrial operating conditions.

구조 시스템 및 재료

After evaluating the operating environment and service life requirements, AISI 304 stainless steel was selected for the entire load-bearing structure system to balance corrosion resistance, mechanical performance, and long-term maintenance cost.

- The supply scope covered fully drawing-based custom fabrication, including:

- Custom-fabricated stainless steel columns for primary load transfer

- Stainless steel beams manufactured strictly according to issued structural drawings

- Perforated stainless steel plates with hole patterns, spacing, and tolerances defined by client specifications

All components were produced for on-site assembly, making dimensional accuracy, hole positioning, and fabrication consistency critical to project success.

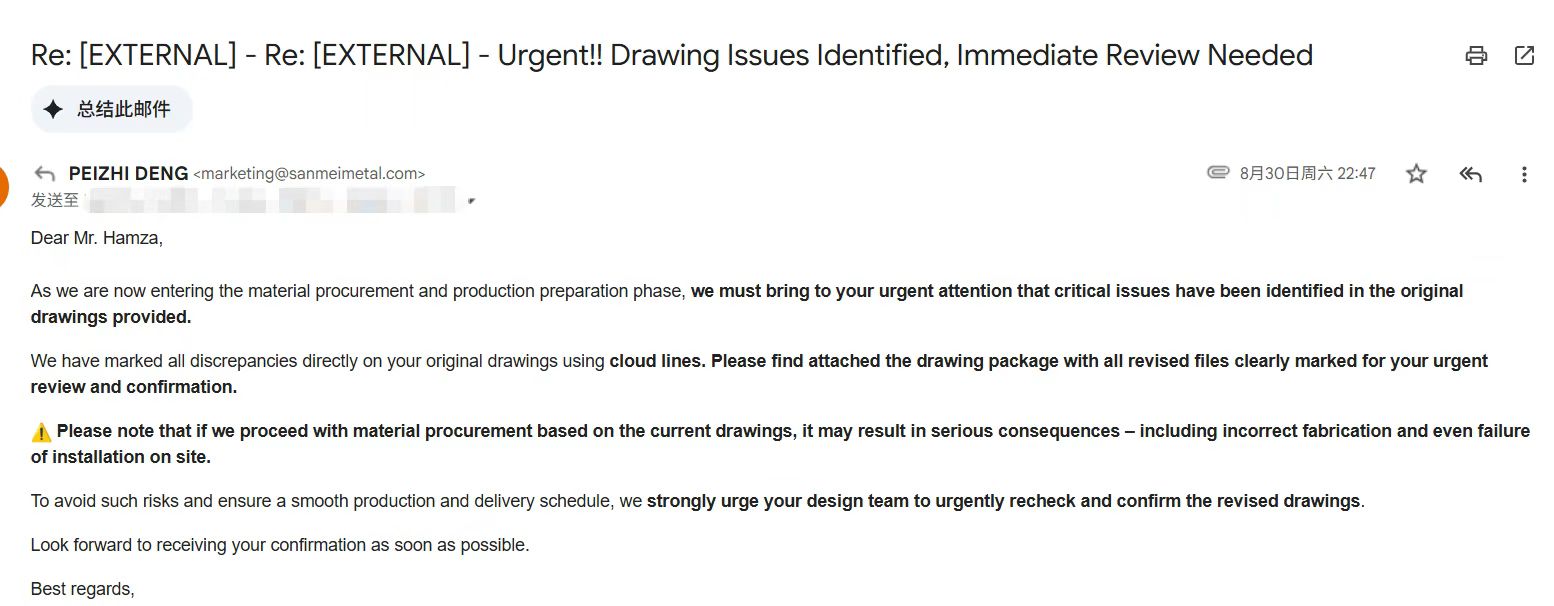

Engineering Review & Risk Mitigation

Although the project was executed based on client-issued drawings, Sanmei Metal conducted a pre-fabrication engineering review as part of its internal risk-control process.

During this review, Sanmei’s engineering team identified a critical structural inconsistency in the original design that could have resulted in load transfer failure and potential collapse under operational conditions.

- Rather than proceeding passively, Sanmei immediately:

- Flagged the risk with clear technical reasoning

- Coordinated directly with the client’s engineering team

- Supported the revision of key structural details before fabrication

This early-stage intervention eliminated a major safety risk and prevented costly rework or operational failure after installation.

Fabrication & Quality Control

Following approval of the revised drawings, fabrication was carried out under controlled processing standards tailored for stainless steel structural applications.

- To meet the client’s compliance requirements, Sanmei fully supported a client-appointed third-party inspection agency, including:

- Coordination of inspection schedules and hold points

- Preparation of material certificates and fabrication documentation

- On-site support for dimensional checks, material traceability, and workmanship verification

In addition, Sanmei assisted in optimizing the inspection workflow, allowing inspection activities to be completed efficiently without disrupting production progress—improving both transparency and execution speed.

Project Summary

Daily production updates enabled remote monitoring and effective coordination throughout fabrication, inspection, and delivery. The project scope included hygiene-driven material selection, verification of structural logic beyond issued drawings, and controlled fabrication and inspection processes, supporting safe installation and long-term operational use.