Custom Steel Structure Systems for Industrial & Commercial Projects

Custom steel structure fabrication for projects where structural reliability, material accountability, and execution control truly matter.

Backed by 100+ completed engineering projects, certified fabrication partners, and verified steel material sources, Sanmei delivers steel structure systems built for real-world performance — not just drawings.

What We Deliver for Projects

Columns, beams, connection components, and related materials are supplied based on project drawings and application requirements, with fabrication scope and material selection adapted to each project’s structural and installation needs.

Proven by 100+ Engineering Projects

Sanmei has delivered steel structure solutions across a wide range of applications, including:

- Industrial facilities and processing plants

- Hygienic and high-humidity environments

- Commercial and utility building structures

- Custom stainless steel load-bearing systems

Each project follows a drawing-based fabrication workflow, supported by engineering review, material traceability, and controlled manufacturing execution — ensuring that what is designed is exactly what gets delivered on site.

Our Steel Structure Projects

View Engineering Projects선택된 프로젝트

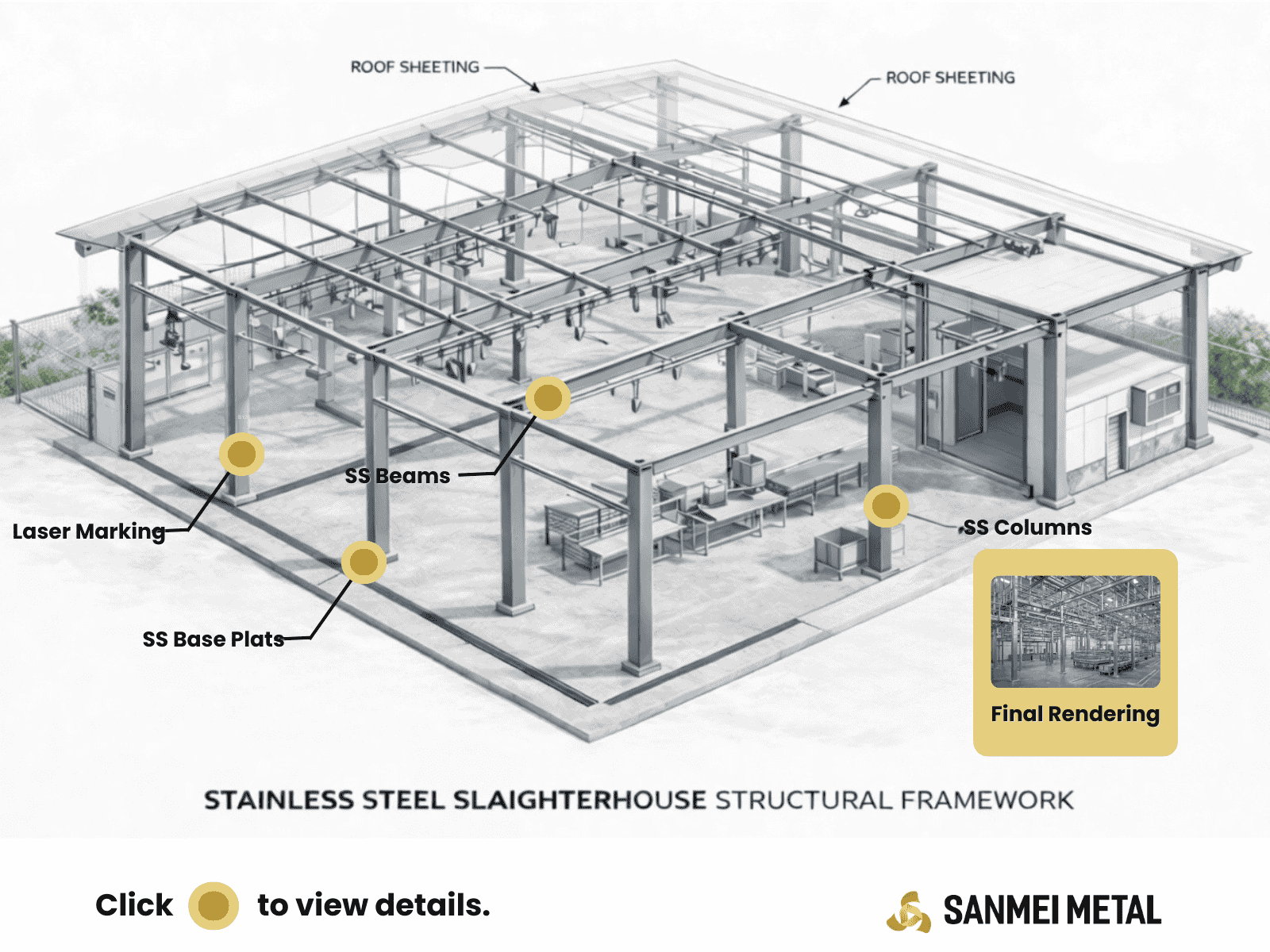

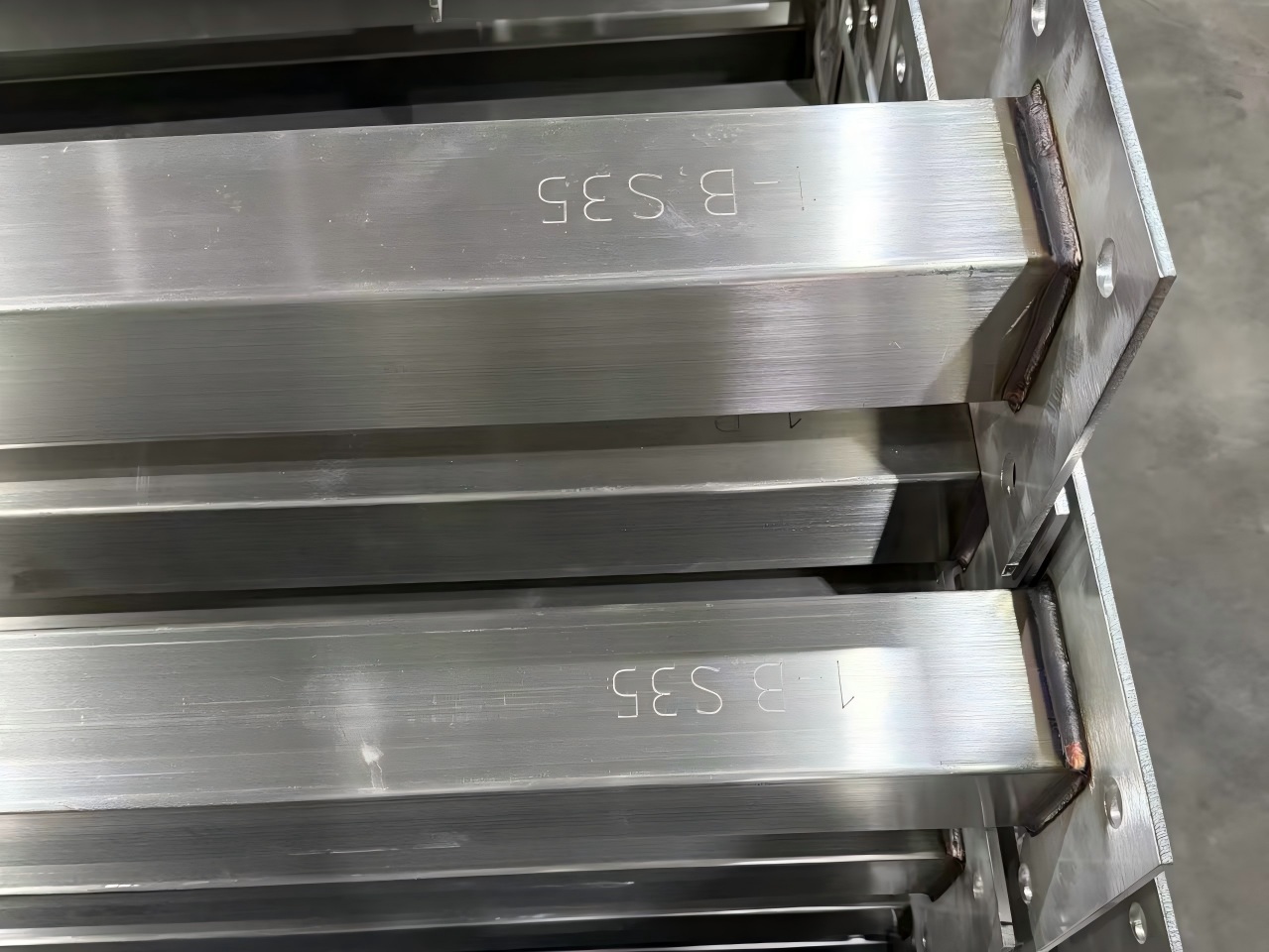

This project involves a 304 stainless steel weighing structure designed for slaughterhouse environments with high humidity and strict hygiene requirements.

The entire system is fabricated from stainless steel square tubes.

For easier on-site identification and installation, laser-marked numbering is applied to all major structural components.

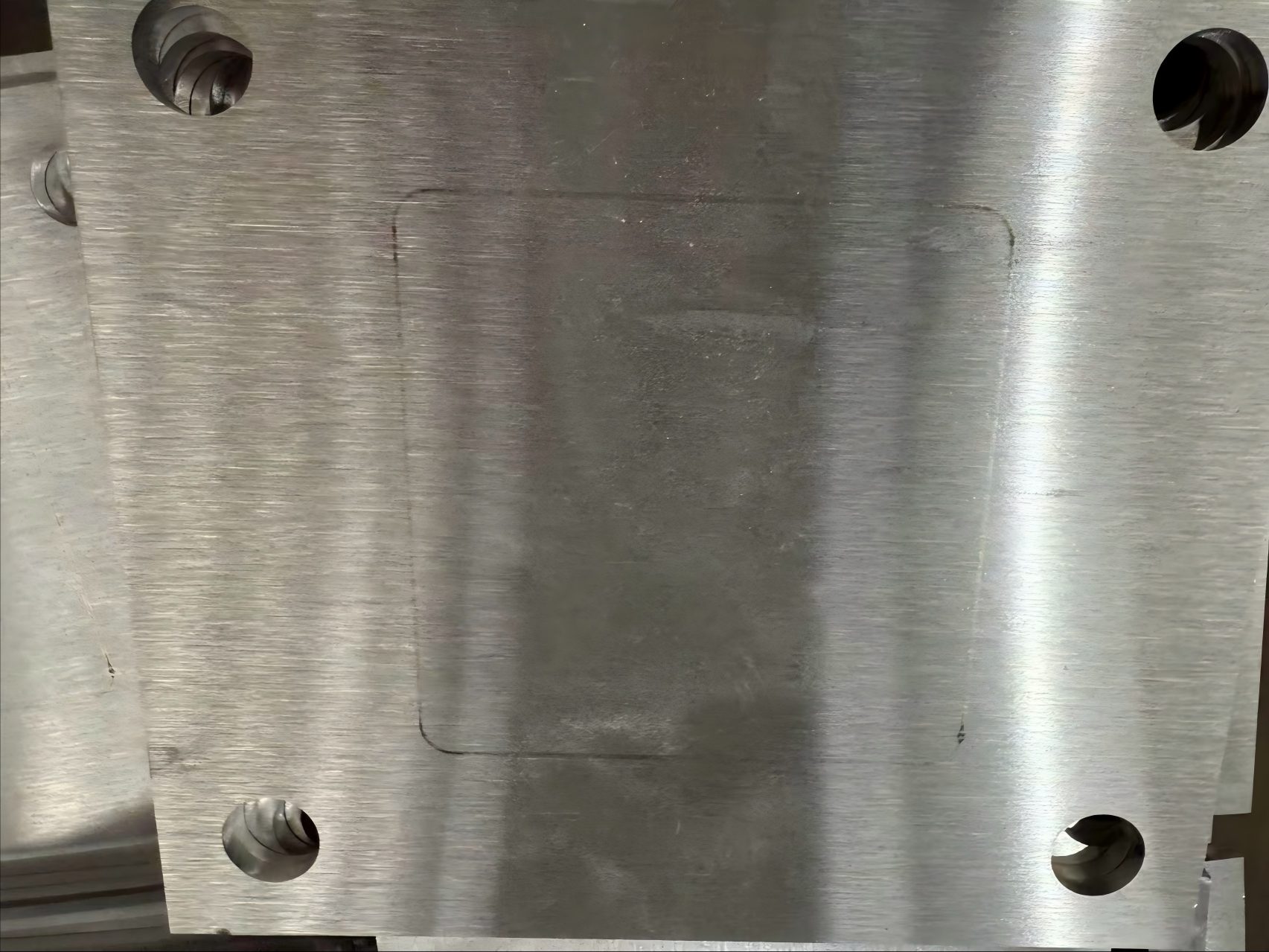

Stainless Steel Base Plates

All base plates are perforated in advance, with hole positions reserved for accurate and efficient on-site installation.

Stainless Steel Columns

The columns are fabricated from square tubes formed from 304 stainless steel plates.

A stainless steel base plate is welded at the bottom of each column, with pre-drilled holes reserved for installation and anchoring.

Stainless Steel Beams

The beams are also made from 304 stainless steel square tubes.

Unlike the columns, stainless steel plates are welded both at the top and bottom of each beam to facilitate structural connection and installation.

All connection plates are pre-drilled according to the project drawings.

Laser Marking

Laser marking is used to permanently identify each major component, improving installation accuracy and long-term traceability.

Final Rendering

Engineering Review Before Fabrication

Steel structure projects often rely on client-issued drawings. However, drawings alone do not eliminate structural risk.

Before fabrication begins, Sanmei’s engineering team conducts a technical review of structural drawings, focusing on load assumptions, connection logic, and assembly feasibility.

This process has repeatedly identified potential design risks prior to manufacturing — helping prevent costly rework, installation delays, or structural failure during operation.

Our role is not to redesign your project, but to verify structural logic before steel is cut.

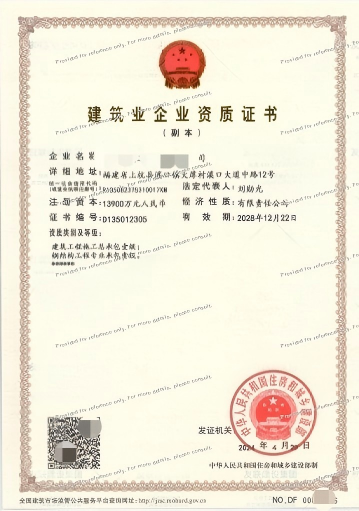

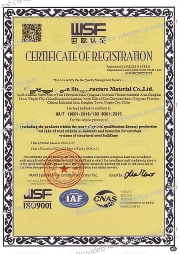

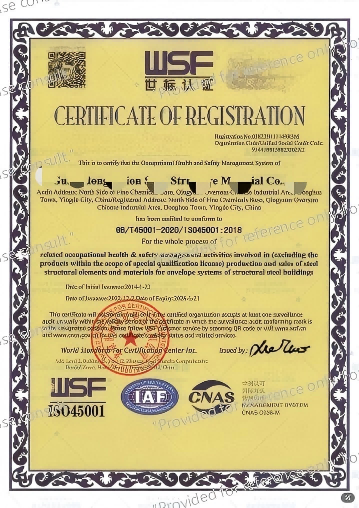

Certified Fabrication & Construction-Compliant Partners

Our steel structure projects are supported by fabrication partners holding recognized construction and engineering qualifications, operating under established quality and compliance systems.

This ensures that structural components are produced in accordance with project execution standards commonly required for industrial and commercial builds — from welding control and dimensional accuracy to documentation and inspection readiness.

Verified Steel Materials from Trusted Mills

All steel used in our structure projects is sourced from verified mills within our long-term supply network — the same material sources we rely on for our own engineering deliveries.

This ensures consistent material performance, stable chemical composition, and full accountability from raw steel to finished structure.

Material documentation typically includes mill test reports, batch identification, and processing records, enabling traceability throughout the project lifecycle.

Explore Our Material Capabilities

더 알아보세요Planning a Steel Structure Project?

If you are planning a steel structure project and need a supplier who understands engineering responsibility, material accountability, and project execution, we’re ready to support.

Whether your project is at concept stage or already under detailed design, we can help assess feasibility, material selection, and fabrication approach before production begins.