Нержавеющая сталь для изготовления ножей: Основные сведения (2024-2033)

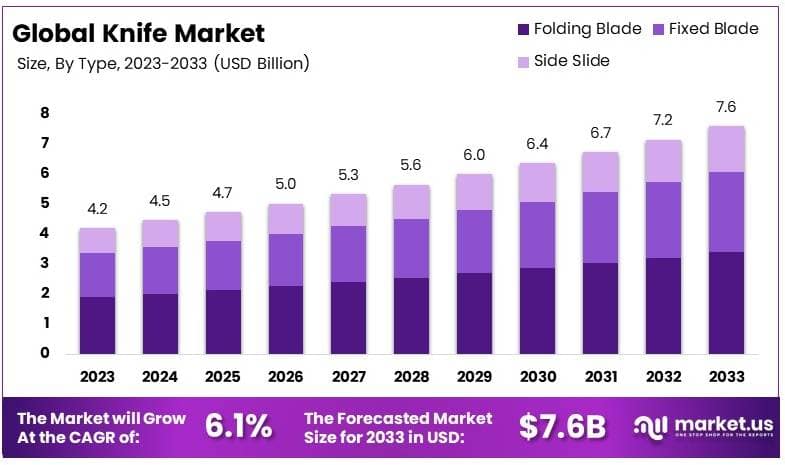

Сайт мировой рынок ножей по прогнозам, достигнет $7,6 млрд к 2033 году, Это обусловлено растущим спросом в различных сегментах, таких как кухонное, тактическое и туристическое использование. Сталь остаётся доминирующим материалом в производстве ножей, обеспечивая более 601 TP3T производства. В этой категории нержавеющая сталь является предпочтительным выбором.

В этом экспертном руководстве мы объясняем, почему нержавеющая сталь является предпочтительным выбором для изготовления ножей, и рекомендуем лучшие сорта для разных типов ножей. на основе тенденций рынка 2023 года и прогнозов рынка в 2033 году.

Это абсолютно практический совет!

Почему нержавеющая сталь идеально подходит для изготовления ножей

Коррозионная стойкость

Коррозионная стойкость нержавеющей стали делает её идеальным материалом для ножей, подверженных воздействию влаги, кислот и агрессивных сред. Это свойство присуще кухонным, тактическим и туристическим ножам. В то время как углеродистая сталь требует тщательного ухода для предотвращения ржавчины, ножи из нержавеющей стали требуют минимального ухода. Для превосходной коррозионной стойкости отлично подходят такие марки стали, как 316, 304 и 316L. Эти марки отлично подходят для использования в условиях высокой влажности, например, в прибрежных районах или на море.

Прочность и долговечность

Нержавеющая сталь обладает исключительной прочностью, что делает её надёжной как для тяжёлых ножей (например, охотничьих), так и для прецизионных инструментов (например, кухонных). Сталь 440C и S30V идеально подходят для высокопрочных изделий, а стали 420J2 и 410 обеспечивают баланс прочности и экономичности для ножей общего назначения. Сталь 316 и 304, предназначенная для ножей, работающих в экстремальных условиях, обеспечивает как долговечность, так и коррозионную стойкость, что делает её идеальным материалом для тактического и охотничьего использования.

Сохранение кромки и твердость

Нержавеющая сталь превосходно сохраняет остроту режущей кромки, что делает её идеальным материалом для ножей, которым требуется длительная острота. Такие марки стали, как S30V, VG10 и 440C, популярны благодаря своей твёрдости и способности сохранять остроту режущей кромки, идеально подходящей для тактических, охотничьих и кухонных ножей премиум-класса. Такие стали, как 420J2 и 410, обеспечивают хорошую стойкость режущей кромки для повседневных кухонных ножей, сочетая лёгкость заточки и долговечность. Более высокая твёрдость, например, 58–60 HRC, характерная для S30V, улучшает сохранение остроты режущей кромки, но может потребовать больше усилий для заточки.

Низкие эксплуатационные расходы

В отличие от ножей из углеродистой стали, которые требуют регулярной смазки, ножи из нержавеющей стали легко чистить и ухаживать за ними. Они обладают высокой устойчивостью к влаге и пятнам, что делает их идеальными для домашней кухни и профессиональных поваров. Такие марки стали, как 304, 410 и 420J2, обычно используются для изготовления кухонных ножей, предлагая решения, не требующие особого ухода, но при этом долговечные. Это особенно важно для занятых поваров или домашних кулинаров, которым нужны надёжные ножи, требующие минимального ухода.

Эстетическая привлекательность

Полированная поверхность нержавеющей стали придаёт ножам элегантный и привлекательный вид. Это особенно важно для высококачественных поварских ножей и коллекционных тактических клинков, где внешний вид дополняет общее мастерство изготовления. Способность нержавеющей стали приобретать блестящую и прочную поверхность делает её идеальным материалом для ножей, которые одновременно функциональны и эстетичны. Кроме того, нержавеющую сталь можно ковать с уникальными узорами, например, дамасскую сталь, что подчёркивает красоту клинка.

Ключевые моменты для производителей ножей на растущем рынке

Как мировой рынок ножей продолжает расширяться, особенно на развивающихся рынках, таких как Ближний Восток, Африка и Латинская Америка, Производители ножей сталкиваются с необходимостью выбора материалов, отвечающих эксплуатационным требованиям и учитывающих меняющиеся предпочтения потребителей. Рост сегментов тактических и походных ножей, а также устойчивая популярность высококачественных кухонных ножей подчеркивают потребность в материалах, подходящих для самых разных сфер применения.

Рынок всё больше отдаёт предпочтение прочным и неприхотливым в уходе ножам, что отражает изменение потребительских предпочтений в пользу продукции, сочетающей в себе функциональность и простоту ухода. Поскольку всё больше людей занимаются активным отдыхом, например, кемпингом и пешим туризмом, растёт спрос на высокопроизводительные инструменты, способные выдерживать суровые условия. Рынок снаряжения для кемпинга и пешего туризма в США оценивается в 8,61 млрд долларов США в 2024 годуи ожидается, что среднегодовой темп роста составит 4,2% с 2024 по 2030 год, еще больше повышают спрос на прочные и высокопроизводительные ножи для активного отдыха. Эта тенденция подчеркивает важность материалов, сочетающих в себе прочность, коррозионную стойкость и экономическую эффективность.

Более того, Ближний Восток и Африка постепенно выходят на рынок ножей, ориентируясь преимущественно на кухонные инструменты и принадлежности, чему способствует рост индустрии гостеприимства и кулинарии. В Латинской Америке рынок ножей стабильно развивается, особенно в таких странах, как Бразилия и Аргентина, где растёт интерес к кулинарии и общению. Эта тенденция открывает перед производителями возможности удовлетворить растущий спрос на кухонные ножи и кухонные принадлежности в этих регионах.

Соответствие марок нержавеющей стали перспективным типам ножей

Теперь давайте проанализируем наиболее подходящие марки нержавеющей стали для ключевых подрынков ножей: ножи для активного отдыха, охоты, кухонные и тактические ножи.

Ножи для активного отдыха

Они требуют превосходной коррозионной стойкости и прочности. 440С и 316 Нержавеющие стали идеально подходят для использования во влажных и суровых условиях на открытом воздухе благодаря своей долговечности и устойчивости к ржавчине.

Охотничьи ножи

Они должны обладать прочностью и сохранять остроту режущей кромки при интенсивном использовании. С30В и Д2 являются идеальным выбором, обладая превосходной твёрдостью и сохранением режущей кромки, что делает их идеальными для сложных задач резки. Хотя сталь 440C также может использоваться, она, как правило, не такая прочная, как S30V или D2, которые обеспечивают лучшее сохранение режущей кромки в сложных условиях.

Кухонные ножи

Важнейшее значение имеют коррозионная стойкость и сохранение кромок. 304, 316 и 410 Нержавеющая сталь отлично подходит для поварских, чистящих и универсальных ножей, обеспечивая превосходное сочетание производительности и простоты ухода.

Тактические ножи

Эти ножи должны выдерживать экстремальные условия, сохраняя при этом исключительную прочность и сохранение остроты режущей кромки. С30В и Д2 Нержавеющие стали являются лучшим выбором для высокопроизводительных применений, обеспечивая непревзойденную долговечность в жестких условиях.

Данные о твердости нержавеющей стали для принятия обоснованных решений

Понимание твёрдости различных марок нержавеющей стали критически важно для определения их пригодности для различных применений ножей. Вы можете сомневаться в пригодности рекомендуемых мной марок. Для удобства я составил список твёрдости каждого типа нержавеющей стали, чтобы вы могли с ними ознакомиться.

Марка нержавеющей стали | HRC (твердость по Роквеллу) | HV (твердость по Виккерсу) | Возможности приложения |

304 | 18-30 | 170-250 | Высокая устойчивость к коррозии, идеально подходит для кухонных ножей, но низкая твердость делает его менее подходящим для длительного сохранения остроты режущей кромки. |

316 | 20-30 | 200-280 | Отличная устойчивость к коррозии, идеально подходит для судовых ножей, высококачественных кухонных ножей и туристического инструмента. Средняя твёрдость. |

440С | 58-60 | 600-800 | Высокая твердость, исключительная стойкость режущей кромки, идеально подходит для тактических и охотничьих ножей. |

С30В | 58-60 | 650-800 | Превосходное сохранение остроты режущей кромки, высокая стойкость к коррозии, используется для высокопроизводительных тактических, охотничьих и EDC ножей. |

ВГ10 | 59-61 | 600-820 | Пользуется популярностью у японских кухонных ножей высокого класса, обеспечивает отличное сохранение режущей кромки и легкость заточки. |

D2 (полунержавеющая) | 58-60 | 600-850 | Превосходная износостойкость и прочность, используется в тактических ножах и ножах для выживания. Более низкая коррозионная стойкость по сравнению с цельнометаллическими сталями. |

2205 Дуплекс | 45-50 | 450-500 | Отличная прочность и устойчивость к коррозии, подходит для тактических ножей и ножей для выживания, которые эксплуатируются в экстремальных условиях. |

Ключевое объяснение:

- HRC (твердость по Роквеллу): Эта шкала измеряет твёрдость стали. Более высокое значение HRC указывает на более высокую твёрдость, что часто связано с лучшим сохранением режущей кромки, но может сделать сталь более хрупкой.

- HV (твердость по Виккерсу): Эта шкала измеряет твёрдость по размеру отпечатка, оставленного алмазным наконечником. Шкала HV точнее, чем HRC, и часто используется в промышленности.

Заключение

Нержавеющая сталь — превосходный материал для изготовления ножей, сочетающий в себе коррозионную стойкость, прочность, долговечность и сохранение остроты режущей кромки. Выбирая подходящую марку стали, производители ножей могут обеспечить оптимальную производительность любых типов ножей, от кухонных лезвий до тактических инструментов. Выбор правильной марки стали для конкретного применения — ключ к удовлетворению растущего спроса на высококачественные, не требующие особого ухода ножи как на развитых, так и на развивающихся рынках.

Если вы все еще задаетесь вопросом «Итак, какая нержавеющая сталь лучше всего подходит для изготовления ножей?»

Запомните эту мнемоническую поговорку:

Для кухонных ножей выбирайте сталь марки 304 или 316, устойчивую к коррозии и не подверженную ржавчине;

Для тактических ножей выбирайте S30V или D2, острые и прочные;

Для походных ножей — 440C или 316, прочные и устойчивые к ржавчине.

В компании Sanmei Metal мы предлагаем широкий ассортимент марок нержавеющей стали, включая 304, 316, 410, 420J2, и 2205, Разработаны с учётом разнообразных потребностей производителей ножей. Если вы ищете лучшую нержавеющую сталь для производства ножей или у вас есть вопросы о нашей продукции, свяжитесь с нами. связаться с нами В любое время. Мы поможем вам выбрать правильные материалы для изготовления ножей.