Adquira o seu LIVRE Acesso: Dossier da Siderúrgica #1 da China

Orientado para o comprador: combine fábricas por grau/acabamento/largura-espessura/aplicação

BAOWUTsingshanLiscoTisco

PVD significa Deposição física de vapor — um processo de alta tecnologia em que o metal é vaporizado a vácuo e depositado como uma camada fina e dura sobre o aço inoxidável. Isso cria acabamentos de cores brilhantes, resistentes a riscos e anticorrosivos como ouro rosa, preto e muito mais.

A Sanmei Metal utiliza um método atualizado chamado Revestimento contínuo de folha única, oferecendo melhor qualidade do que as linhas de revestimento tradicionais.

O processo da Sanmei é construído em torno de corte por cisalhamento voador e revestimento PVD contínuo, garantindo cor mais consistente e planura superior em pedidos de grande volume. Combinado com um camada anti-impressão digital em nanoescala, este método proporciona resultados significativamente melhores resistência ao desgaste (comprovado por mais de 1000 ciclos no teste MEK) e estabilidade visual em comparação com o revestimento estático tradicional em lote. É uma solução mais confiável para aplicações arquitetônicas e de eletrodomésticos de alta qualidade.

| Recurso | Sanmei Metal – Revestimento Contínuo | Revestimento tradicional chinês (estilo lote) |

|---|---|---|

| Processo de revestimento | Revestimento a vácuo contínuo em chapas cortadas voando | Revestimento a vácuo estático em folhas empilhadas |

| Uniformidade de cor | Excelente consistência entre lotes | Variação frequente entre lotes |

| Planicidade da folha | Corte antes do revestimento — sem deformação por calor | Deformação comum devido ao calor durante o revestimento |

| Camada anti-impressão digital | Película nanotransparente — clara e durável | Acabamento básico — menos durável |

| Durabilidade (Teste MEK)* | ≥1000 fricções | 300–800 fricções |

| Graus de aço suportados | Série 200 / 300 / 400 (gama completa) | Geralmente apenas 201 ou 304 |

| Item | Detalhes |

|---|---|

| Tipos de aço | Séries 200, 300, 400 |

| Acabamento de superfície | Base espelhada ou acetinada |

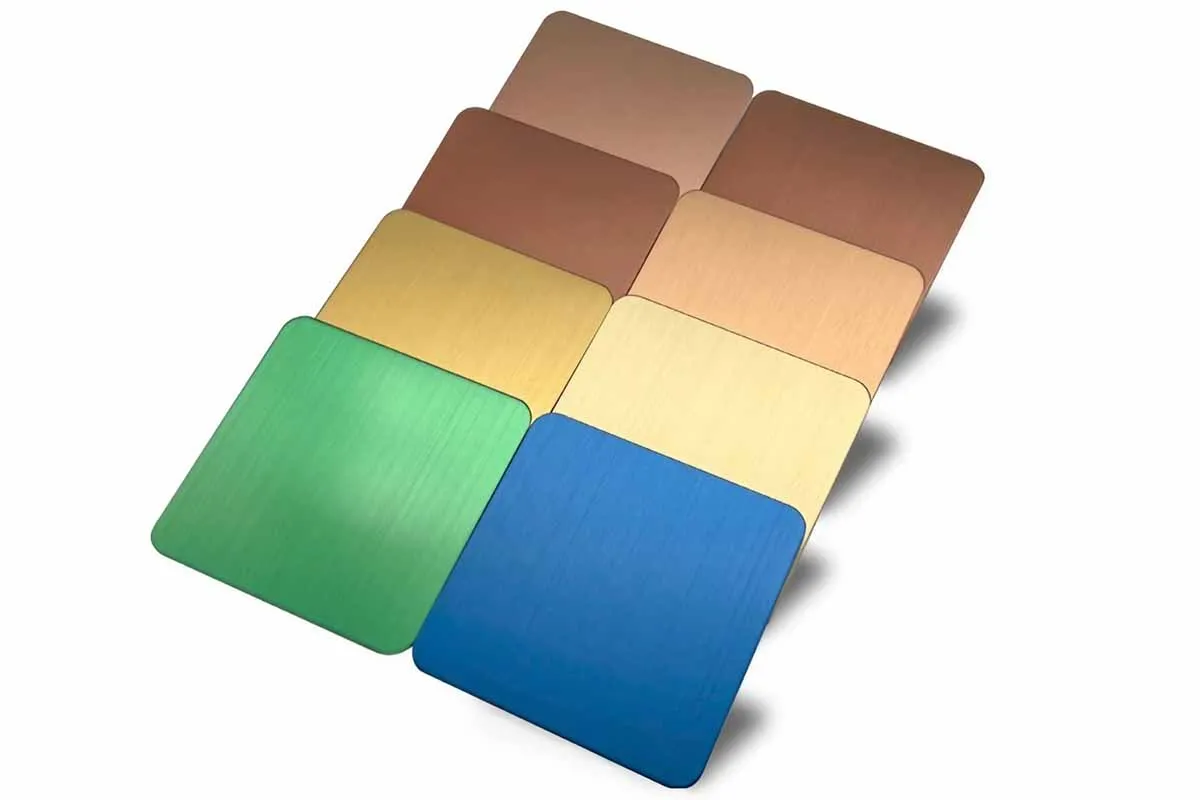

| Opções de cores | Ouro Rosa, Vermelho Rosé, Titânio Preto e muito mais |

| Camada anti-impressão digital | Revestimento transparente em nanoescala — resistente a arranhões e manchas |

| Teste de Durabilidade (MEK) | ≥1000 fricções — excelente resistência a solventes |

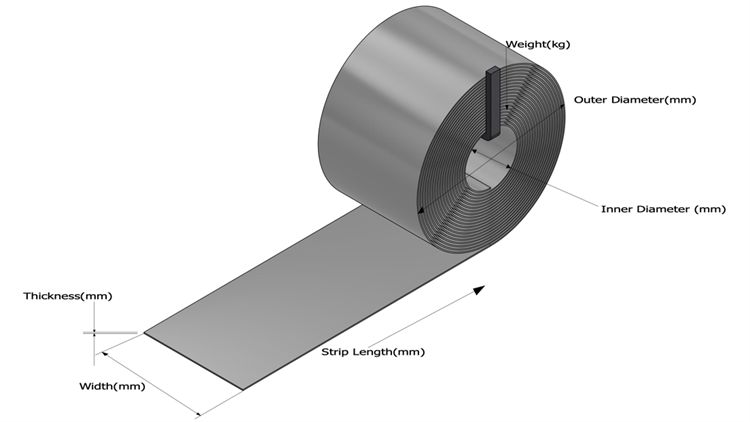

| Nota | Moinho de origem | Largura * Comprimento (mm) | Espessura (mm) | Acabamentos | Acabamento de moinho |

| 201 | Hongwang, Lisco | 1000 mm * 2000 mm (3'4" * 6'6") 1219 mm * 2438 mm (4' * 8') 1219 mm * 3048 mm (4' * 10') 1500 mm * 3000 mm (4'11" * 9'10") | 0.3-3.0 | Revestimento PVD | BA/2B |

| 304L | Yongjin, Jisco, Posco Pzss, Tisco, Lisco | ||||

| 316 | Posco Pzss, Tisco | ||||

| 316L | Posco Pzss, Tisco | ||||

| 304 | Yongjin, Jisco, Posco Pzss, Tisco, Lisco | 1000 * 2000 mm (3'4" * 6'6") 1219 * 2438/3048 mm mm (4' * 8'/10') 1250 * 2000/2438/3048/3000 mm (4'1" * 6'6"/8'/10'/ 9'10") 1500 * 3000 mm (4'11" * 9'10") | |||

| 430 | Jisco, Krupp |

Sim! PVD (Physical Vapor Deposition) é um dos revestimentos mais duráveis disponível. Ao contrário da galvanoplastia tradicional, oferece:

Sim, O aço inoxidável revestido com PVD é totalmente seguro para superfícies de contato com alimentos, tornando-o ideal para equipamentos de cozinha e interiores de restaurantes.

Enquanto PVD é mais caro do que os revestimentos padrão, isso é durabilidade excepcional e apelo estético torná-lo uma escolha econômica a longo prazo. Reduz custos de manutenção e prolonga a vida útil do produto.

| Recurso | Revestimento PVD | Revestimento de água |

| Durabilidade | Altamente resistente a riscos (mais de 1000 ciclos) | Sujeito a arranhões e desbotamento |

| Longevidade da cor | Dura mais de 10 anos sem desbotar | Pode desaparecer em 1-2 anos |

| Eco-amizade | Não são utilizados produtos químicos tóxicos | Envolve produtos químicos nocivos |

| Eficiência de custos | Maiores custos iniciais e menores custos a longo prazo | Menor investimento inicial, reaplicação frequente necessária |

Sede:

Centro de Criação, nº 142, Rua Yuhe, Cidade de Lecong, Distrito de Shunde, Cidade de Foshan, Província de Guangdong, China. 528315

Fábrica: Cidade Logística de Liyuan, Cidade de Chencun, Distrito de Shunde, Cidade de Foshan, Província de Guangdong, China. 528313

Base de apoio local na Austrália: (Yatala, QLD) – Chegando em 2026