Obtén tu GRATIS Acceso: Expediente de la planta siderúrgica #1 de China

Orientado al comprador: Buscar molinos que se ajusten a las necesidades del cliente según el grado, el acabado, el ancho, el espesor y la aplicación.

BAOUWUTsingshanLiscoTisco

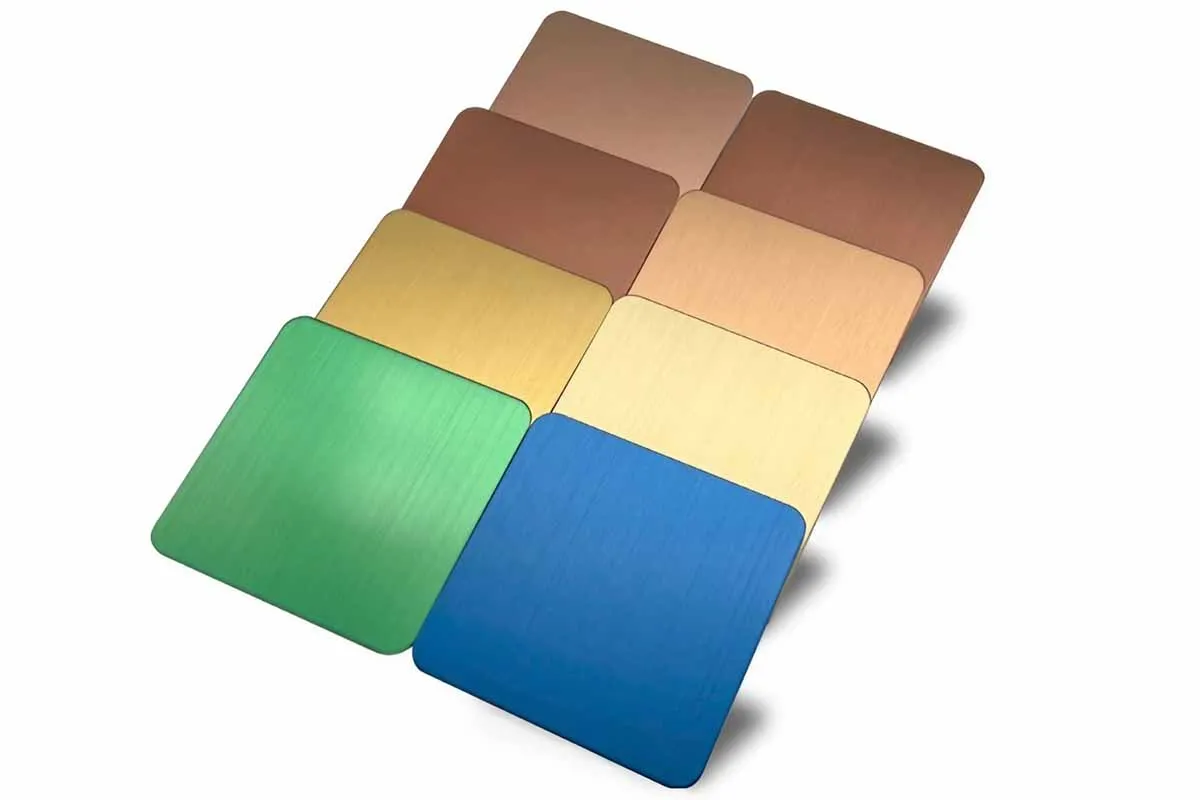

Degradación fotovoltaica (PVD) significa Deposición física de vapor — un proceso de alta tecnología en el que el metal se vaporiza al vacío y se deposita como una capa delgada y dura sobre el acero inoxidable. Esto crea Acabados de color brillantes, resistentes a los arañazos y anticorrosión. como el oro rosa, el negro y más.

Sanmei Metal utiliza un método mejorado llamado Recubrimiento continuo de una sola hoja, ofreciendo una mejor calidad que las líneas de recubrimiento tradicionales.

El proceso de Sanmei se basa en Corte con cizalla volante y recubrimiento PVD continuo, asegurando Color más consistente y planitud superior en pedidos de gran volumen. Combinado con un capa antihuellas a escala nanométricaEste método ofrece resultados significativamente mejores. resistencia al desgaste (probado por más de 1000 ciclos en la prueba MEK) y estabilidad visual en comparación con el recubrimiento estático por lotes tradicional. Es una solución más confiable para Aplicaciones arquitectónicas y de electrodomésticos de alta gama.

| Característica | Sanmei Metal – Recubrimiento continuo | Recubrimiento tradicional chino (estilo por lotes) |

|---|---|---|

| Proceso de recubrimiento | Recubrimiento continuo al vacío sobre láminas cortadas al vuelo | Recubrimiento estático al vacío sobre láminas apiladas |

| Uniformidad del color | Excelente consistencia de lote a lote | Variación frecuente entre lotes |

| Planitud de la hoja | Corte antes del recubrimiento: sin deformación por calor | Deformación común debido al calor durante el recubrimiento. |

| Capa antihuellas | Película nanotransparente: clara y duradera | Capa superior básica: menos duradera |

| Durabilidad (Prueba MEK)* | ≥1000 frotaciones | 300–800 frotaciones |

| Grados de acero admitidos | Serie 200/300/400 (gama completa) | Generalmente solo 201 o 304 |

| Artículo | Detalles |

|---|---|

| Tipos de acero | Serie 200, 300, 400 |

| Acabado de la superficie | Base de espejo o satinada |

| Opciones de color | Oro rosa, rojo rosado, titanio negro y más |

| Capa antihuellas | Recubrimiento transparente a escala nanométrica: resistente a rayones y manchas |

| Prueba de durabilidad (MEK) | ≥1000 frotaciones: excelente resistencia a los disolventes |

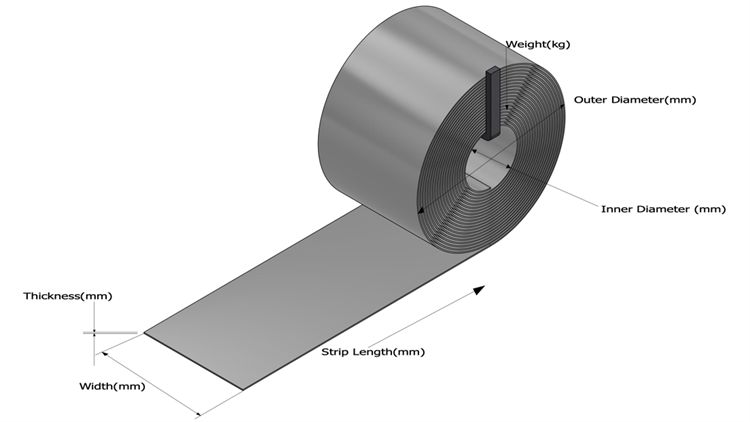

| Calificación | Molino de origen | Ancho * Largo (mm) | Espesor (mm) | Acabados | Acabado de molino |

| 201 | Hongwang, Lisco | 1000 mm x 2000 mm (3'4" x 6'6") 1219 mm * 2438 mm (4' * 8') 1219 mm * 3048 mm (4' * 10') 1500 mm x 3000 mm (4'11" x 9'10") | 0.3-3.0 | Recubrimiento PVD | Licenciatura/2B |

| 304L | Yongjin, Jisco, Posco Pzss, Tisco, Lisco | ||||

| 316 | Posco Pzss, Tisco | ||||

| 316L | Posco Pzss, Tisco | ||||

| 304 | Yongjin, Jisco, Posco Pzss, Tisco, Lisco | 1000 * 2000 mm (3'4" * 6'6") 1219 * 2438/3048 mm (4' * 8'/10') 1250 * 2000/2438/3048/3000 mm (4'1" * 6'6"/8'/10'/ 9'10") 1500 * 3000 mm (4'11" * 9'10") | |||

| 430 | Jisco, Krupp |

¡Sí! PVD (deposición física de vapor) es uno de los recubrimientos más duraderos Disponible. A diferencia de la galvanoplastia tradicional, ofrece:

Sí, El acero inoxidable recubierto de PVD es completamente seguro para superficies en contacto con alimentos, lo que lo hace ideal para equipos de cocina e interiores de restaurantes.

Mientras El PVD es más caro que los recubrimientos estándar, es durabilidad excepcional y atractivo estético lo convierte en una opción rentable a largo plazo. Reduce costos de mantenimiento y prolonga la vida útil del producto.

| Característica | Recubrimiento PVD | Recubrimiento de agua |

| Durabilidad | Altamente resistente a los arañazos (más de 1000 ciclos) | Propenso a rayarse y decolorarse |

| Longevidad del color | Dura más de 10 años sin decolorarse. | Puede desvanecerse en 1-2 años. |

| Respeto al medio ambiente | No se utilizan productos químicos tóxicos | Implica sustancias químicas nocivas |

| Eficiencia de costos | Costos iniciales más altos y costos a largo plazo más bajos | Menor costo inicial, se requiere reaplicación frecuente |

Sede:

Centro de Creación, n.º 142, calle Yuhe, pueblo de Lecong, distrito de Shunde, ciudad de Foshan, provincia de Guangdong, China. 528315

Fábrica: Ciudad Logística de Liyuan, Pueblo de Chencun, Distrito de Shunde, Ciudad de Foshan, Provincia de Guangdong, China. 528313

Base de apoyo local de Australia: (Yatala, QLD) – Próximamente en 2026