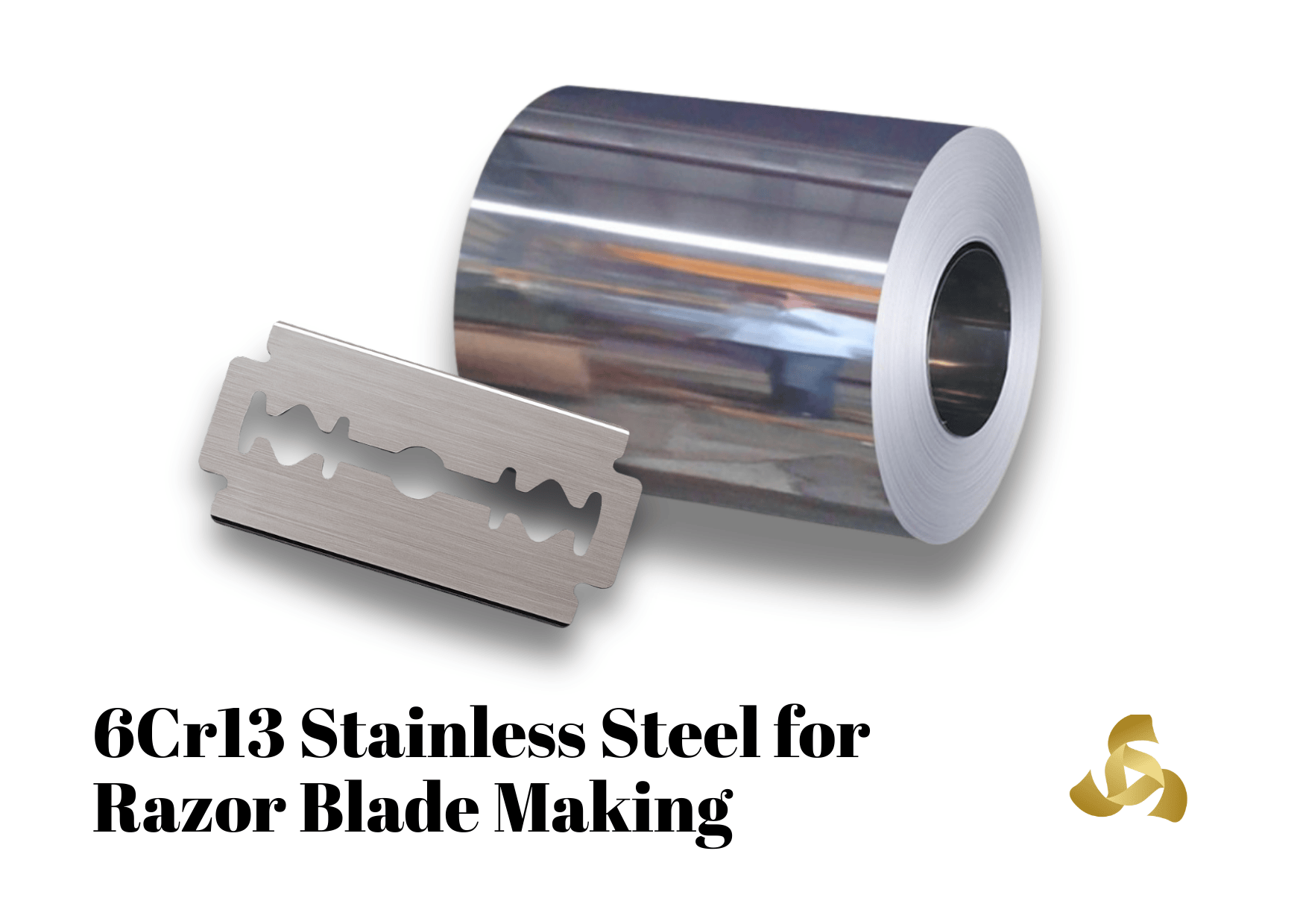

5 razones por las que los fabricantes de hojas de afeitar confían en el acero 6Cr13

En el mundo de la fabricación de cuchillas, la elección de acero de hoja de afeitar El acero incide directamente no solo en el rendimiento, sino también en la rentabilidad, la durabilidad y la satisfacción del usuario. Si bien se utilizan diversos tipos de acero en las herramientas de corte, como el acero al carbono, el acero aleado y el acero para herramientas, material de la hoja de afeitar debe cumplir con un estándar más alto: nitidez, resistencia a la corrosión y retención constante del filo en condiciones de uso húmedo.

Entre todas las opciones, Acero inoxidable martensítico 6Cr13 Se destaca como la opción predilecta de la industria. Pero, ¿qué lo hace tan confiable y cómo se compara con otros grados de acero en aplicaciones de afeitado en el mundo real? Analicemos cinco razones principales.

1. Cumple con la definición oficial de acero para hojas de afeitar.

Antes de seleccionar un material, los fabricantes deben asegurarse de que se ajuste a las definiciones globales para la aplicación de hojas de afeitar. Según la Comisión de Comercio Internacional de los Estados Unidos, acero de hoja de afeitar Se define no solo por su composición, sino también por su forma: bobinas laminadas planas de menos de 23 mm de ancho y 0,266 mm de espesor.

El 6Cr13 cumple exactamente estos criterios:

Contenido de cromo entre 12%–14,5%

Contenido de carbono alrededor de 0,60%

Estructura martensítica que se endurece para ofrecer un filo fino.

Esto permite una geometría de hoja precisa y de alto rendimiento manteniendo la durabilidad y la resistencia al desgaste.

2. Ofrece el mejor equilibrio entre los materiales de hoja de acero inoxidable.

Pero la conformidad no lo es todo: el verdadero rendimiento depende de cómo un material se adapte al uso práctico. El acero inoxidable para hojas de afeitar destaca por su resistencia a la humedad y la oxidación, lo que lo hace ideal para maquinillas expuestas al agua.

En comparación con el acero al carbono, el 6Cr13 ofrece una combinación óptima de:

Fuerte resistencia a la corrosión en condiciones húmedas o mojadas.

Dureza de hasta ~58 HRC después del tratamiento térmico.

Trabajabilidad en procesos de producción de bandas delgadas laminadas en frío

Estas propiedades ayudan a reducir las quejas de los usuarios sobre oxidación, reemplazos frecuentes o pérdida prematura de brillo.

Para obtener una perspectiva más amplia sobre las ventajas de los aceros inoxidables martensíticos en aplicaciones húmedas, consulte Revisión técnica de Alleima.

3. Coincide con lo que los usuarios realmente quieren

Comprender las características del material es importante, pero también lo es escuchar a quienes usan el producto. En uno Hilo de Reddit de la comunidad del afeitado, Los usuarios compartieron fuertes preferencias en torno al peso, la resistencia a la oxidación y la sensación táctil.

Esta retroalimentación informal pero reveladora refuerza lo que los profesionales ya saben:

| Material | Valor percibido | Durabilidad | Sensación del usuario | Perspectiva del mercado |

|---|---|---|---|---|

| Acero inoxidable | Alta | De por vida+ | Sólido, confiable | La “navaja para siempre”; preferida por su resistencia a la corrosión |

| Titanio | De primera calidad | De por vida+ | Ligero y cálido. | Cómodo pero le falta peso para algunos usuarios. |

| Latón / Bronce | Tradicional | Siglo+ | Pesado, clásico | Aspecto vintage, desarrolla pátina. |

| Aluminio | Moderado | Limitado | Ultraligero | Apto para viajes, menos duradero. |

| Zamak | Bajo | Corto | Luz | Nivel de entrada, propenso a la corrosión si falla el recubrimiento. |

Los consumidores priorizan constantemente nitidez, longevidad del borde, y resistencia a la oxidación—precisamente los puntos fuertes del 6Cr13.

4. Supera a aceros similares para hojas de afeitar.

Además de las opiniones de los usuarios y el rendimiento en el laboratorio, los fabricantes también deben tomar decisiones inteligentes basándose en la ciencia comparativa de los materiales. Dentro de la serie CR de aceros inoxidables martensíticos, el 6Cr13 ofrece el mejor equilibrio entre dureza, resistencia y resistencia a la corrosión.

La siguiente tabla la compara con 4Cr13 y 3Cr13, comunes en cuchillas de gama media o económica. Referencia: Análisis de Xirui Blade.

| Calificación | Carbono % | Potencial de dureza | Fortalezas | Limitaciones | Uso típico |

|---|---|---|---|---|---|

| 6Cr13 | 0.60% | ★★★★☆ | Alta dureza, resistencia a la corrosión, equilibrio. | Retención moderada del filo bajo tensión repetida | Cuchillas de alto rendimiento (maquinillas de afeitar, tijeras) |

| 4Cr13 | 0.40% | ★★★☆☆ | Procesamiento más fácil, resistencia decente. | Menor dureza, no ideal para hojas de precisión. | Herramientas de aseo de nivel medio |

| 3Cr13 | 0.30% | ★★☆☆☆ | Rentable y fácil de moldear | Suave, se desgasta más rápido. | Cuchillas de nivel de entrada o decorativas |

Una nota de matiz: Si bien el 6Cr13 no es el acero más duro ni el más exótico disponible (por ejemplo, en comparación con los aceros de metalurgia en polvo), está optimizado especialmente para máquinas de afeitar de uso húmedo. Para aplicaciones exigentes más allá del afeitado, como cuchillas industriales o herramientas quirúrgicas, se pueden considerar otros aceros. Pero para las máquinas de afeitar, es difícil de superar.

5. Está probado, disponible y es escalable: respaldado por Sanmei Metal

Por supuesto, seleccionar la opción correcta material de la hoja de afeitar No significa nada si no se puede obtener de forma fiable ni escalar a producción. Ahí es donde entra Sanmei Metal.

Nosotros suministramos acero inoxidable 6Cr13 En tiras laminadas planas de precisión, diseñadas específicamente para cuchillas de afeitar. Nuestras capacidades internas nos permiten ofrecer:

📏 Tolerancias dimensionales estrictas

🔬 Acabados superficiales personalizados (BA, 2B, espejo)

🧪 Propiedades mecánicas consistentes, lote a lote

🛠️ Apoyo en I+D para la optimización del filo de la cuchilla

🔄 Volúmenes flexibles: desde lotes de prueba hasta producción a gran escala

Acero inoxidable 6Cr13

Hablemos del acero para hojas de afeitar

¿Necesita una alta dureza y resistencia a la corrosión? material de la hoja de afeitar ¿Que funciona en todas las líneas de fabricación y mercados?

Buscando un proveedor que entienda la metalurgia y ¿La industria del afeitado?

Contacte con Sanmei Metal hoy para solicitar muestras, especificaciones técnicas o consultas de aplicación.

[…] ofreciendo una protección superior contra la oxidación y prolongando la vida útil de la hoja. La estructura martensítica del acero 6Cr13 garantiza una excelente […]