Seninkini al ÖZGÜR Erişim: Çin'in #1 Çelik Fabrikası Dosyası

Alıcı Odaklı: Değirmenleri kalite/bitiş/genişlik-kalınlık/uygulama açısından eşleştirin

BAOWUTsingşanLiscoTisco

Ayrıntıları ve Örnekleri Görüntüle →

Tedarik ettiğimiz **6Cr13**, hassas bıçak üretiminde üstün ürün performansına doğrudan katkıda bulunan olağanüstü metalurjik özellikleriyle tanınmaktadır. Bu özellikler özellikle şunları sağlar:

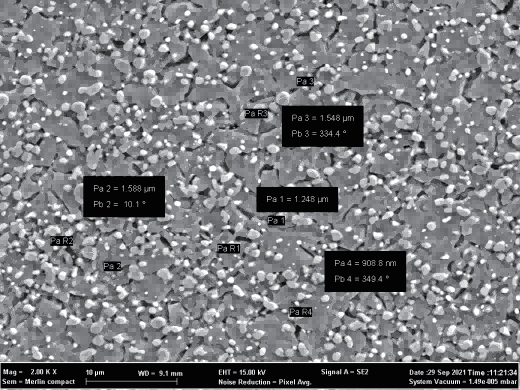

Düşük makrosegregasyon – şerit boyunca homojen kimyasal dağılımını sağlayarak kenar işleme sırasındaki değişimi azaltır ve parti tutarlılığını artırır.

İnce dağılmış karbürler – Temiz kesme ve hassas bıçak kenarı taşlamasını destekler, daha pürüzsüz kesme performansı ve daha iyi aşınma direnci sağlar.

Mükemmel ısıl işlem tepkisi – şerit boyunca istikrarlı sertlik kontrolüne olanak tanır, söndürme ve temperlemeden sonra tutarlı mekanik özellikler sağlar, bu da tıraş bıçağı ve cerrahi bıçak kalitesi için kritiktir.

6Cr13 Mekanik Özellikleri (Tavlanmış, 25°C):

Akma Dayanımı (Rp0.2): ≥ 590 MPa

Uzama: ≥ 15%

Sertlik: HB ≤ 235 | HRB ≤ 99

6Cr13 Paslanmaz Çelik Kimyasal Bileşimi

| Standart | Seviye | C | Si | Mn | P | S | Cr | Hayır | V | N |

|---|---|---|---|---|---|---|---|---|---|---|

| S/JGBXG002-2019 | 6Cr13 | 0,60–0,70 | ≤0,80 | ≤1.00 | ≤0,035 | ≤0,005 | 13.00–14.00 | ≤0,30 | 0,05–0,20 | / |

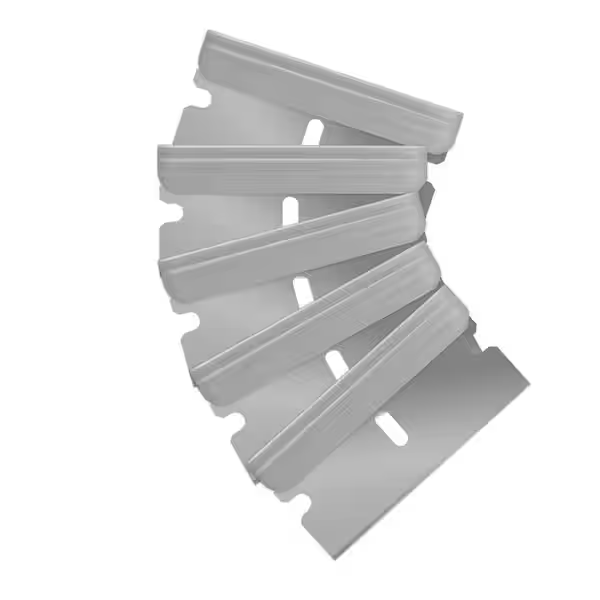

Bunlar arasında; jilet üretimi Malzeme düzlüğü, karbür kontrolü ve ısıl işlem tepkisi konusunda en katı gereklilikleri karşılayan bu uygulama, 6Cr13 malzememizin gücünü ortaya koyan öne çıkan bir uygulamadır. Bu segmenti yalnızca teknik gereklilikleri nedeniyle değil, aynı zamanda küresel tıraş endüstrisindeki OEM ve proje bazlı müşterileri aktif olarak desteklediğimiz için de öne çıkarıyoruz.

Aynı zamanda 6Cr13 paslanmaz çeliğimiz güvenilir bir çözüm olarak hizmet vermektedir bıçak malzemesi Hassasiyetin, sertliğin ve korozyon direncinin önemli olduğu diğer endüstrilerde.

Ayrıca şurada da mevcuttur: bobinler, levhalar, şeritler veya diğer özelleştirilmiş şekiller Belirli işleme ve uygulama ihtiyaçlarını karşılamak için. Parti ve fırın numarasına göre tedarik ettiğimiz için, Özel siparişleriniz ve stok durumunuz için lütfen bizimle iletişime geçiniz.

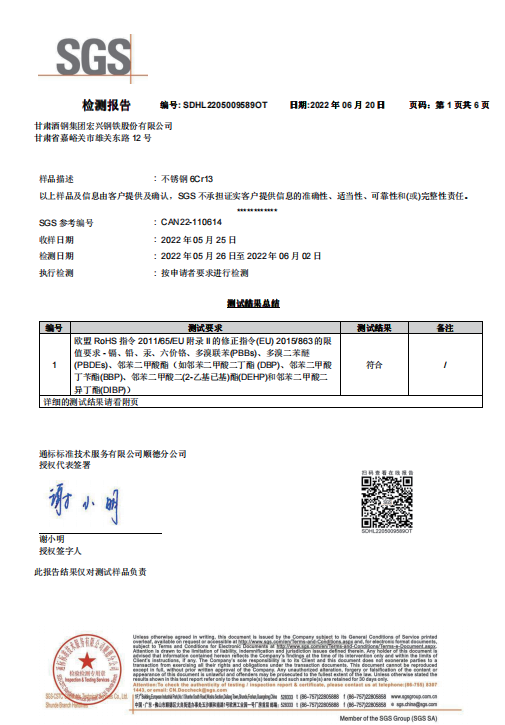

Sanmei'nin 6Cr13 paslanmaz çeliği, uluslararası alanda tanınan doğrulama ile desteklenmektedir ve bu sayede müşterilerimize hem kalite hem de izlenebilirlik güvencesi sağlanmaktadır.

Parti Başına Değirmen Sertifikası: Her bobin belirli bir fırın numarasına kadar izlenebilir ve ilgili değirmen sertifikasıyla birlikte tedarik edilir.

SGS Üçüncü Taraf Denetimi: Talep üzerine mekanik ve kimyasal özellikleri doğrulamak için bağımsız test raporları mevcuttur.

Geri Dönüştürülmüş Malzeme Doğrulaması: Ortak fabrikalarımız, %'den fazla geri dönüştürülmüş içeriğe sahip martensitik paslanmaz çelik tedarik etmek için SGS sertifikasına sahiptir. Bu sertifika, müşterilerimizin sürdürülebilirlik hedeflerini ve ESG veya yeşil tedarik girişimlerine uyumlarını desteklemektedir.

Sanmei Metal, 8K, Saç Çizgisi, Damgalı, PVD renkli kaplama, Antik, Parmak İzi Önleyici, Laminat, Kabartma vb. dahil olmak üzere dekoratif paslanmaz çelik saclar sağlayabilir.

Tüm süreç, devir teslimler sırasında bilgi boşluklarını ve zamanı azaltmak için özel bir kişi tarafından yürütülür.

Karargah:

Çin, Guangdong Eyaleti, Foshan Şehri, Shunde Bölgesi, Lecong Kasabası, Yuhe Yolu, No.142, İnşaat Merkezi. 528315

Fabrika: Liyuan Lojistik Şehri, Chencun Kasabası, Shunde Bölgesi, Foshan Şehri, Guangdong Eyaleti, Çin. 528313

Avustralya Yerel Destek Üssü: (Yatala, QLD) – 2026'da geliyor