Seninkini al ÖZGÜR Erişim: Çin'in #1 Çelik Fabrikası Dosyası

Alıcı Odaklı: Değirmenleri kalite/bitiş/genişlik-kalınlık/uygulama açısından eşleştirin

BAOWUTsingşanLiscoTisco

Ayrıntıları ve Örnekleri Görüntüle →

PVD anlamına gelir Fiziksel Buhar Biriktirme — Metalin vakumda buharlaştırılıp paslanmaz çeliğe ince ve sert bir kaplama olarak yerleştirildiği ileri teknoloji bir işlem. Bu, parlak, çizilmeye dayanıklı ve korozyona dayanıklı renkli kaplamalar gül rengi altın, siyah ve daha fazlası gibi.

Sanmei Metal, geliştirilmiş bir yöntem kullanıyor Tek Sayfalık Sürekli KaplamaGeleneksel kaplama hatlarından daha iyi kalite sunuyor.

Sanmei'nin süreci şu şekilde oluşturulmuştur: uçan kesme ve sürekli PVD kaplama, sağlanması daha tutarlı renk ve üstün düzlük büyük hacimli siparişlerde. Birleştirilmiş nano ölçekli parmak izi önleyici katmanBu yöntem önemli ölçüde daha iyi sonuçlar verir aşınma direnci (MEK testinde 1000'den fazla döngü ile kanıtlanmıştır) ve geleneksel statik parti kaplamaya kıyasla görsel stabilite. Daha güvenilir bir çözümdür üst düzey mimari ve ev aletleri uygulamaları.

| Özellik | Sanmei Metal – Sürekli Kaplama | Geleneksel Çin Kaplama (Toplu Stil) |

|---|---|---|

| Kaplama İşlemi | Uçan kesim levhalar üzerinde sürekli vakum kaplama | Yığılmış levhalar üzerinde statik vakum kaplama |

| Renk Tekdüzeliği | Mükemmel partiden partiye tutarlılık | Partiler arasında sık sık değişiklik |

| Sayfa Düzlüğü | Kaplamadan önce kesilir — ısı deformasyonu olmaz | Kaplama sırasında ısıdan dolayı eğilme yaygındır |

| Parmak İzi Önleyici Katman | Nano-şeffaf film — şeffaf ve dayanıklı | Temel son kat — daha az dayanıklı |

| Dayanıklılık (MEK Testi)* | ≥1000 ovma | 300–800 ovma |

| Desteklenen Çelik Sınıfları | 200 / 300 / 400 serisi (tam seri) | Genellikle sadece 201 veya 304 |

| Öğe | Detaylar |

|---|---|

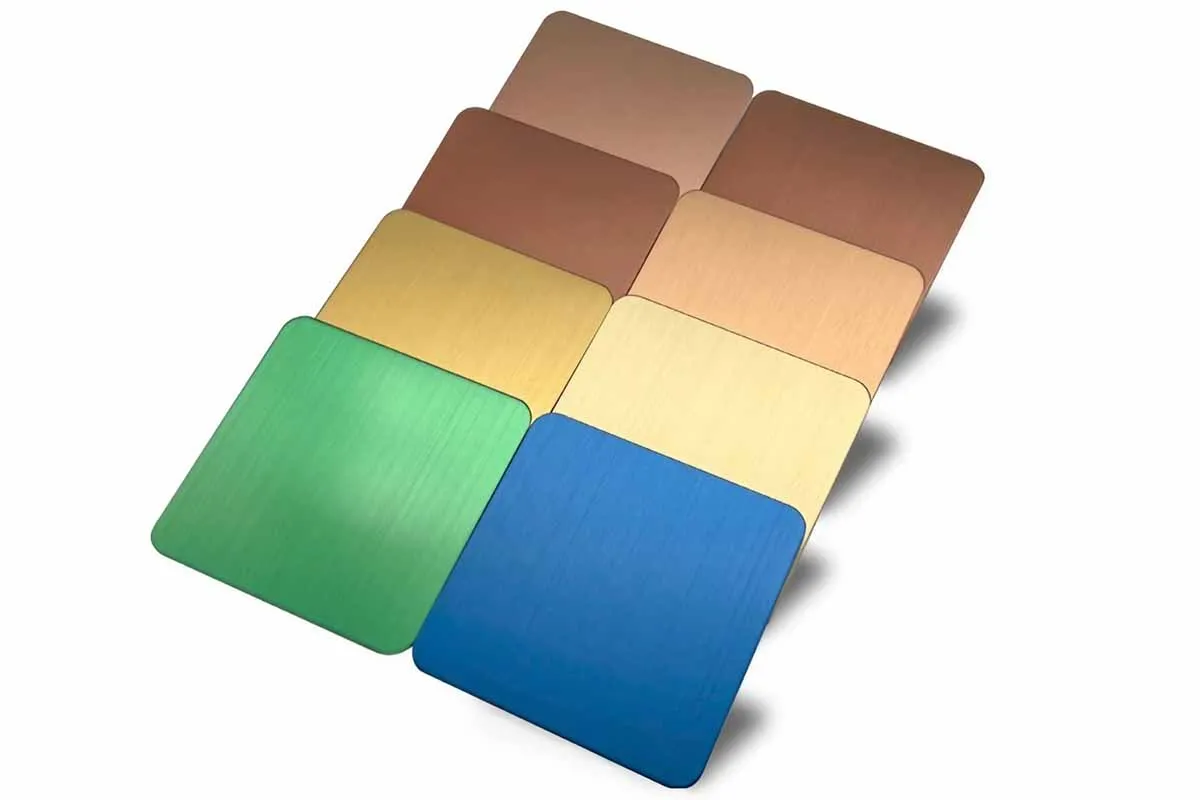

| Çelik Türleri | 200, 300, 400 Serisi |

| Yüzey Kaplama | Ayna veya Saten Taban |

| Renk Seçenekleri | Gül Altın, Rosé Kırmızı, Siyah Titanyum ve daha fazlası |

| Parmak İzi Önleyici Katman | Nano ölçekli şeffaf kaplama - çizilmeye ve lekeye dayanıklı |

| Dayanıklılık Testi (MEK) | ≥1000 sürtünme — çözücülere karşı mükemmel direnç |

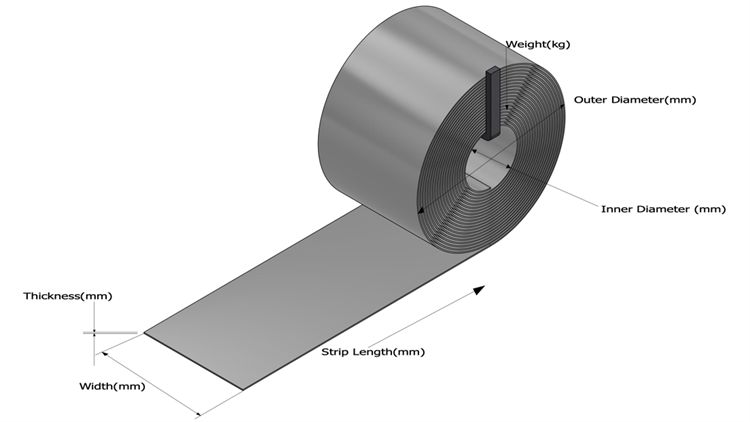

| Seviye | Köken Değirmeni | Genişlik * Uzunluk(mm) | Kalınlık(mm) | Bitişler | Değirmen cilası |

| 201 | Hongwang, Lisko | 1000 mm * 2000 mm (3'4" * 6'6") 1219 mm * 2438 mm (4' * 8') 1219 mm * 3048 mm (4' * 10') 1500 mm * 3000 mm (4'11" * 9'10") | 0.3-3.0 | PVD Kaplamalı | BA/2B |

| 304L | Yongjin, Jisco, Posco Pzss, Tisco, Lisco | ||||

| 316 | Posco Pzss, Tisco | ||||

| 316L | Posco Pzss, Tisco | ||||

| 304 | Yongjin, Jisco, Posco Pzss, Tisco, Lisco | 1000 * 2000 mm (3'4" * 6'6") 1219 * 2438/3048 mm mm (4' * 8'/10') 1250 * 2000/2438/3048/3000 mm (4'1" * 6'6"/8'/10'/9'10") 1500 * 3000 mm (4'11" * 9'10") | |||

| 430 | Jisco, Krupp |

Evet! PVD (Fiziksel Buhar Biriktirme) en dayanıklı kaplamalardan biridir Mevcuttur. Geleneksel elektrokaplamanın aksine şunları sunar:

Evet, PVD kaplamalı paslanmaz çelik tamamen güvenlidir Gıda ile temas eden yüzeyler için idealdir, bu nedenle mutfak ekipmanları ve restoran iç mekanları için idealdir.

Sırasında PVD, standart kaplamalardan daha pahalıdır, onun olağanüstü dayanıklılık ve estetik çekicilik Uzun vadede uygun maliyetli bir seçim haline getirir. bakım maliyetleri ve ürünün kullanım ömrünü uzatır.

| Özellik | PVD Kaplama | Su Kaplama |

| Dayanıklılık | Yüksek çizilme direnci (1000+ döngü) | Çizilmeye ve solmaya eğilimli |

| Renk Ömrü | Solmadan 10+ yıl dayanır | 1-2 yıl içinde kaybolabilir |

| Çevre dostu | Hiçbir toksik kimyasal kullanılmadı | Zararlı kimyasallar içerir |

| Maliyet Etkinliği | Daha yüksek ön ödeme, daha düşük uzun vadeli maliyetler | Daha düşük peşinat, sık sık yeniden başvuru gerekiyor |

Karargah:

Çin, Guangdong Eyaleti, Foshan Şehri, Shunde Bölgesi, Lecong Kasabası, Yuhe Yolu, No.142, İnşaat Merkezi. 528315

Fabrika: Liyuan Lojistik Şehri, Chencun Kasabası, Shunde Bölgesi, Foshan Şehri, Guangdong Eyaleti, Çin. 528313

Avustralya Yerel Destek Üssü: (Yatala, QLD) – 2026'da geliyor