Hol dir deins FREI Zugang: Chinas #1-Stahlwerksdossier

Käuferorientiert: Passende Walzwerke nach Güteklasse/Oberflächenbearbeitung/Breite-Dicke/Anwendung

BAOWUTsingshanLiscoTisco

Details und Beispiele ansehen →

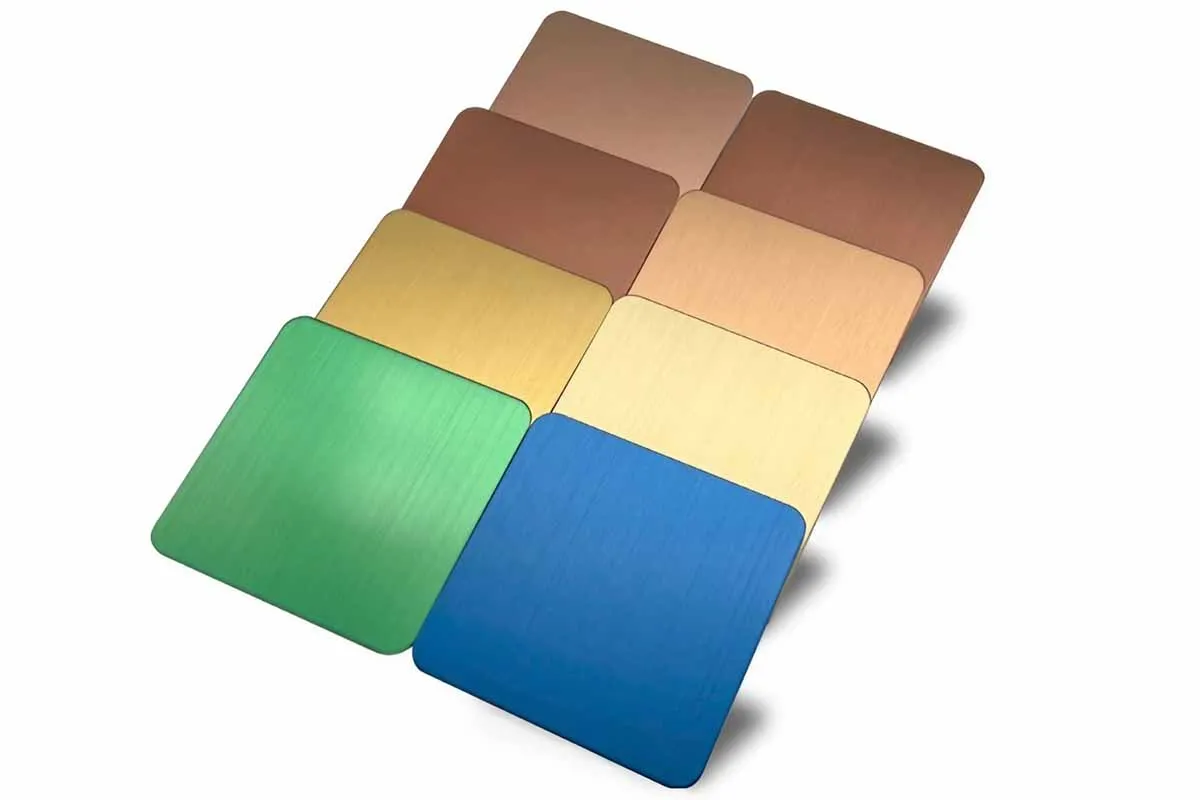

PVD steht für Physikalische Gasphasenabscheidung — ein Hightech-Verfahren, bei dem Metall im Vakuum verdampft und als dünne, harte Schicht auf Edelstahl aufgebracht wird. Dadurch entsteht brillante, kratzfeste und korrosionsbeständige Farboberflächen wie Roségold, Schwarz und mehr.

Sanmei Metal verwendet eine verbesserte Methode namens Einzelblatt-Kontinuierliche Beschichtungund bietet eine bessere Qualität als herkömmliche Beschichtungslinien.

Der Prozess von Sanmei basiert auf fliegendes Scherschneiden und kontinuierliche PVD-Beschichtung, Gewährleistung gleichmäßigere Farbe und bessere Planheit bei Großaufträgen. Kombiniert mit einem Anti-Fingerabdruck-Schicht im Nanomaßstabliefert diese Methode deutlich bessere Verschleißfestigkeit (nachgewiesen durch über 1000 Zyklen im MEK-Test) und visuelle Stabilität im Vergleich zur herkömmlichen statischen Batch-Beschichtung. Es ist eine zuverlässigere Lösung für High-End-Architektur- und Haushaltsgeräteanwendungen.

| Besonderheit | Sanmei Metal – Kontinuierliche Beschichtung | Traditionelle chinesische Beschichtung (Batch-Stil) |

|---|---|---|

| Beschichtungsprozess | Kontinuierliche Vakuumbeschichtung auf fliegend geschnittenen Blechen | Statische Vakuumbeschichtung auf gestapelten Blechen |

| Farbgleichmäßigkeit | Hervorragende Chargenkonsistenz | Häufige Abweichungen zwischen Chargen |

| Blechplanheit | Vor dem Beschichten schneiden – keine Wärmeverformung | Häufiges Verziehen durch Hitze während der Beschichtung |

| Anti-Fingerabdruck-Schicht | Nanotransparente Folie – klar & langlebig | Einfacher Decklack – weniger haltbar |

| Haltbarkeit (MEK-Test)* | ≥1000 Reibungen | 300–800 Reibungen |

| Unterstützte Stahlsorten | 200er / 300er / 400er Serie (volles Sortiment) | Normalerweise nur 201 oder 304 |

| Artikel | Details |

|---|---|

| Stahlsorten | Serie 200, 300, 400 |

| Oberflächenfinish | Spiegel- oder Satinbasis |

| Farboptionen | Roségold, Rosérot, Schwarzes Titan und mehr |

| Anti-Fingerabdruck-Schicht | Transparente Beschichtung im Nanomaßstab – kratz- und wischfest |

| Haltbarkeitstest (MEK) | ≥1000 Reibungen – ausgezeichnete Beständigkeit gegen Lösungsmittel |

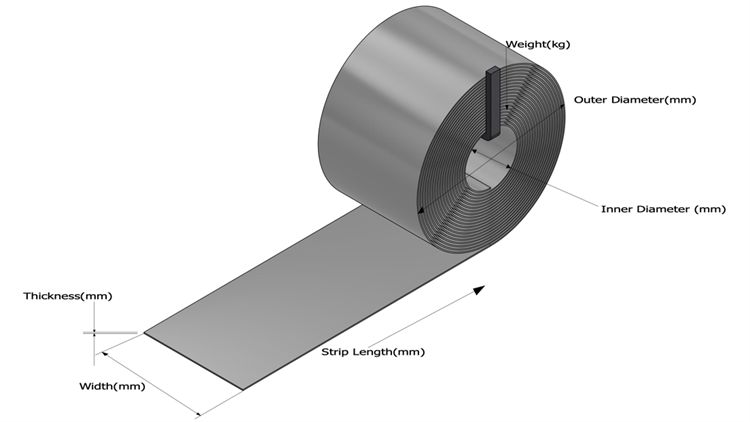

| Grad | Herkunftsmühle | Breite * Länge (mm) | Dicke (mm) | Oberflächen | Walzoberfläche |

| 201 | Hongwang, Lisco | 1000 mm * 2000 mm (3'4" * 6'6") 1219 mm * 2438 mm (4' * 8') 1219 mm * 3048 mm (4' * 10') 1500 mm * 3000 mm (4'11" * 9'10") | 0.3-3.0 | PVD-beschichtet | BA/2B |

| 304L | Yongjin, Jisco, Posco Pzss, Tisco, Lisco | ||||

| 316 | Posco Pzss, Tisco | ||||

| 316L | Posco Pzss, Tisco | ||||

| 304 | Yongjin, Jisco, Posco Pzss, Tisco, Lisco | 1000 * 2000 mm (3'4" * 6'6") 1219 * 2438/3048 mm mm(4' * 8'/10') 1250 * 2000/2438/3048/3000 mm (4'1" * 6'6"/8'/10'/ 9'10") 1500 * 3000 mm (4'11" * 9'10") | |||

| 430 | Jisco, Krupp |

Ja! PVD (Physical Vapor Deposition) ist eine der haltbarsten Beschichtungen verfügbar. Im Gegensatz zur herkömmlichen Galvanisierung bietet es:

Ja, PVD-beschichteter Edelstahl ist absolut sicher für Oberflächen, die mit Lebensmitteln in Berührung kommen, und ist daher ideal für Küchengeräte und Restauranteinrichtungen.

Während PVD ist teurer als Standardbeschichtungen, es ist außergewöhnliche Haltbarkeit und ästhetische Anziehungskraft machen es auf lange Sicht zu einer kostengünstigen Wahl. Es reduziert Instandhaltungskosten und verlängert die Lebensdauer des Produkts.

| Besonderheit | PVD-Beschichtung | Wasserplattierung |

| Haltbarkeit | Hohe Kratzfestigkeit (über 1000 Zyklen) | Anfällig für Kratzer und Verblassen |

| Farbbeständigkeit | Hält über 10 Jahre ohne zu verblassen | Kann in 1–2 Jahren verblassen |

| Umweltfreundlichkeit | Keine Verwendung giftiger Chemikalien | Enthält schädliche Chemikalien |

| Kosteneffizienz | Höhere Vorabkosten, niedrigere langfristige Kosten | Niedrigere Anfangspreise, häufige Neuanwendung erforderlich |

Hauptsitz:

Creating Center, Nr. 142, Yuhe Road, Lecong Town, Shunde District, Foshan City, Guangdong Province, China. 528315

Fabrik: Logistikstadt Liyuan, Stadt Chencun, Bezirk Shunde, Stadt Foshan, Provinz Guangdong, China. 528313

Lokale Support-Basis in Australien: (Yatala, QLD) – Eröffnung 2026