Edelstahl 420 vs. 304: Ein umfassender Materialführer

Die Wahl zwischen Edelstahl 420 und 304 hängt weitgehend von den spezifischen Anforderungen Ihrer Anwendung ab. Beide Sorten haben unterschiedliche Eigenschaften, die sie für verschiedene Branchen geeignet machen. Für die Auswahl des optimalen Werkstoffs ist es jedoch entscheidend, ihre Unterschiede zu kennen. Dieser Artikel bietet einen detaillierten Vergleich, der die wichtigsten Eigenschaften, Anwendungen und neuesten Forschungsergebnisse hervorhebt.

Neugierig, wie sich 420 im Vergleich zu seinen Varianten 420J1 und 420J2 schlägt?

Entdecken Sie den vollständigen Leitfaden: Leitfaden zu Edelstahl 420: J1, J2 und darüber hinaus →

Wichtige Eigenschaften von Edelstahl 420 und 304

Beim Vergleich von rostfreiem Stahl 420 und 304 ist es wichtig, ihre Materialeigenschaften und Leistungsunterschiede zu kennen. Nachstehend finden Sie eine Tabelle mit einer Zusammenfassung der wichtigsten Eigenschaften:

Detaillierte Spezifikationen und Informationen zu den verwendeten Materialien finden Sie auf unseren Produktseiten:

Edelstahl 420

Hohe Härte und ausgezeichnete Schnitthaltigkeit – ideal für Schneidwerkzeuge, Messer und industrielle Bauteile.

Entdecke 420 →Edelstahl 304

Hervorragende Korrosions- und Hitzebeständigkeit – weit verbreitet in Küchengeräten, Architektur und chemischer Industrie.

Erkunden Sie 304 →🔍 Edelstahl-Wissensecke

Möglicherweise bemerken Sie, dass die verwendeten Härteeinheiten für 304 Und Edelstahl 420 Sie unterscheiden sich. Werfen wir einen kurzen Blick darauf, warum und was die einzelnen Einheiten bedeuten.

- HRC (Rockwell C): Wird für härtere Werkstoffe verwendet. Dabei wird ein Diamantkegel oder eine Stahlkugel eingesetzt, um die Eindringtiefe zu messen – typischerweise verwendet für Werkzeugstähle und gehärtete Stähle.

- Hochspannung (Vickers): Verwendet eine Diamantpyramide zur Messung der Eindringtiefe; am besten geeignet für dünnere Bleche oder weichere Metalle.

- HB (Brinell): Wird mit einer großen Stahlkugel auf die Oberfläche aufgebracht; geeignet für raue oder unebene Materialien.

Obwohl HRC und HV nicht direkt vergleichbar sind, lässt sich eine grobe Umrechnung vornehmen:

- 50 HRC ≈ 500 HV — Edelstahl 420 weist eine höhere Härte auf.

- 300 HV ≈ 30 HRC — Edelstahl 304 ist deutlich weicher.

Brauchen Materialprüfungsdaten oder Härteprüfung der Probe?

Kontaktieren Sie das technische Team von SANMEI.

für zertifizierte Werksberichte und Schnittproben.

Eingehender Vergleich von 420 und 304

Korrosionsbeständigkeit

Der rostfreie Stahl 304 bietet eine deutlich bessere Korrosionsbeständigkeit als 420. Er eignet sich hervorragend für nasse und salzige Umgebungen, während 420 eher für trockene oder leicht korrosive Bedingungen geeignet ist. Studien zeigen, dass Chloridionen die Lochfraßbildung bei 304 beschleunigen, während sie bei 420 in trockenen Umgebungen weniger Auswirkungen haben. Die Rostbeständigkeit von 304 in maritimen und industriellen Umgebungen ist der von 420 weit überlegen.

Härte

420 erreicht nach der Wärmebehandlung eine höhere Härte (bis zu 50 HRC) und ist damit ideal für verschleißfeste Anwendungen. Im Gegensatz dazu liegt bei 304 der Schwerpunkt auf Zähigkeit und Duktilität. Die höhere Härte von 420 ist besonders nützlich für Schneidwerkzeuge und abriebfeste Komponenten.

Hitzebeständigkeit

304 kann einer Dauerbelastung von bis zu 870 °C standhalten und übertrifft damit 420, das auf 650 °C begrenzt ist. Die Wärmebehandlung verbessert die Abriebfestigkeit von 420, kann aber seine Bearbeitbarkeit und Schweißbarkeit beeinträchtigen.

Bearbeitbarkeit und Schweißbarkeit

304 ist leichter zu bearbeiten und zu schweißen und erfordert keine besonderen Nachbehandlungen nach dem Schweißen. Im Gegensatz dazu erfordert 420 eine Vorwärmung und Wärmebehandlung nach dem Schweißen, und seine Bearbeitbarkeit nimmt mit zunehmender Härte ab. Jüngste Fortschritte in der Laserschweißtechnik haben die Verformungskontrolle bei dünnen Edelstahlblechen verbessert, wovon 304 profitiert, indem minimale thermische Verformung und präzise Maßkontrolle gewährleistet werden.

Hohe Härte und Haltbarkeit erforderlich?

Anfragen Edelstahl 420 — ideal für Klingen, Werkzeuge und verschleißfeste Teile.

420-Angebot anfordern →Benötigen Sie Korrosionsbeständigkeit?

Anfragen Edelstahl 304 — perfekt für Anwendungen in Küche, Chemie und Architektur.

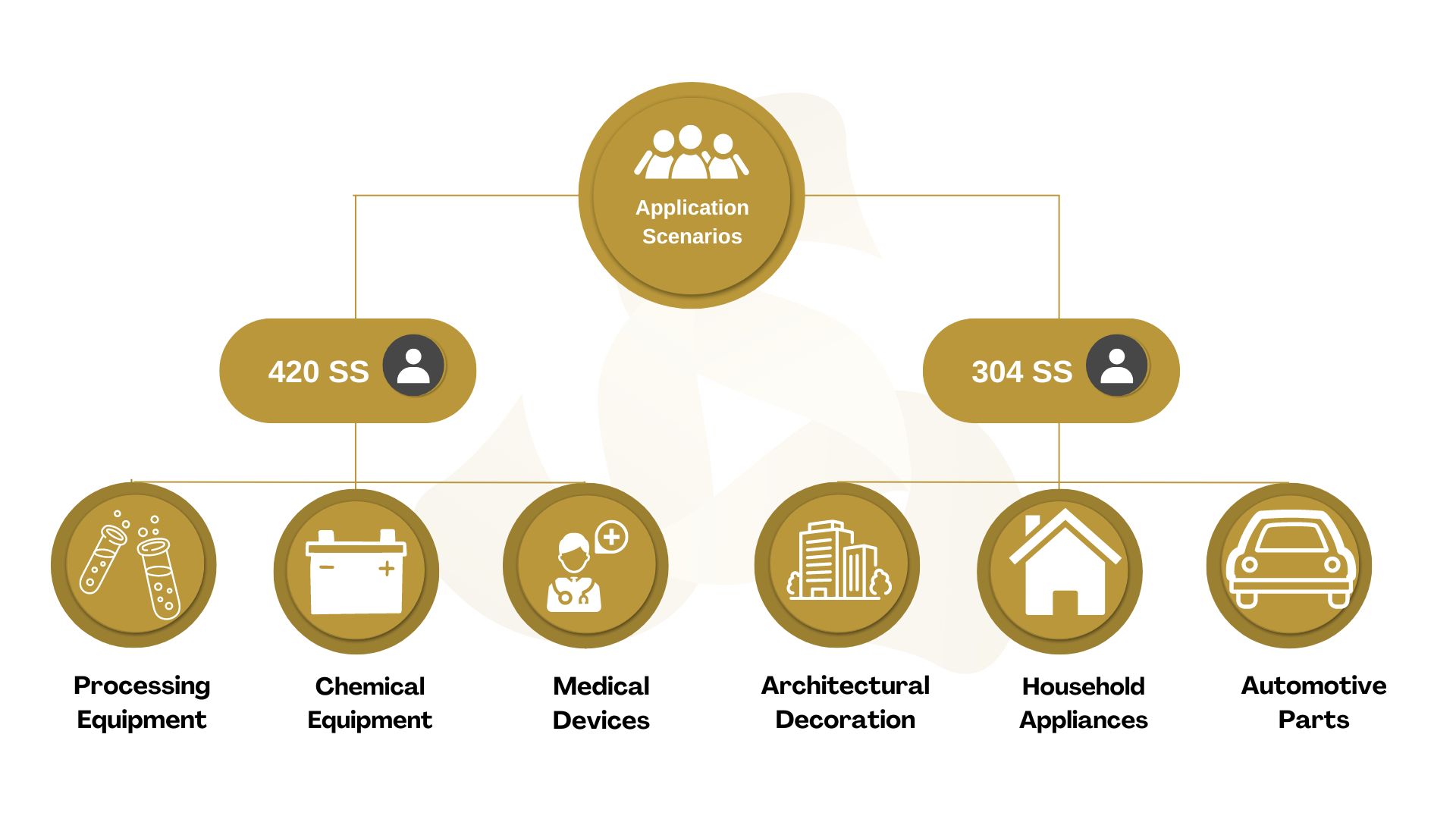

304-Angebot anfordern →Anwendungsspezifischer Vergleich

Um eine fundierte Entscheidung treffen zu können, ist es wichtig zu wissen, wie die einzelnen Sorten in der Praxis abschneiden. Im Folgenden sind einige Beispiele aufgeführt:

Lebensmittelverarbeitungsgeräte

- 420: Durch seine hohe Härte ist es ideal für Schneidemesser und andere stark beanspruchte Komponenten, wie z. B. Fleischwölfe und Schneidemaschinen. Diese Anwendungen erfordern Haltbarkeit und Kantenfestigkeit.

- 304: Aufgrund seiner hohen Korrosionsbeständigkeit eignet es sich hervorragend für saure oder salzhaltige Umgebungen, wie z. B. Brauerei-Tanks, Milchpasteurisierer und Gärbottiche für Wein, wo Hygiene und Langlebigkeit von entscheidender Bedeutung sind.

Studien zeigen, dass 304 in chloridreichen Umgebungen, wie sie in der Lebensmittel- und Getränkeindustrie häufig vorkommen, hervorragend funktioniert.

Sie sind sich nicht sicher, ob Ihr Edelstahl 420 oder 304 wirklich lebensmittelecht ist?

Lesen Sie unseren vollständigen Beschaffungsleitfaden: Wie man echten lebensmittelechten Edelstahl bezieht →

Chemische Ausrüstung

- 420: Geeignet für den Umgang mit milden Säuren und Laugen, häufig verwendet in chemischen Mischern und Pumpenwellen, wo eine mäßige Korrosionsbeständigkeit ausreicht.

- 304: Hervorragende Leistung in aggressiveren chemischen Umgebungen, z. B. in Lagertanks und Leitungen für saure oder salzhaltige Lösungen.

Die Forschung zeigt, dass Sulfat-Ionen und andere Chemikalien die Lochfraßbeständigkeit von nichtrostenden Stählen beeinträchtigen und die überlegene Leistung von 304 im Vergleich zu 420 unter hochkorrosiven Bedingungen unterstreichen.

Suchen Sie geprüfte Lieferanten oder Stahlwerke für Edelstahl 304 und 420?

Entdecken Sie Chinas wichtigste Produktionszentren in unserem Artikel. Die führenden Edelstahlhersteller in China →

Medizinische Geräte

- 420: Seine Härte und Korrosionsbeständigkeit machen es ideal für chirurgische Instrumente wie Skalpelle und Pinzetten, die Präzision und Haltbarkeit erfordern.

- 304: Die einfache Sterilisation und die hervorragende Korrosionsbeständigkeit machen es zum idealen Material für implantierbare Geräte, Krankenhausbetten und chirurgische Tabletts.

Die Fortschritte beim Laserschweißen haben sich als vorteilhaft erwiesen, um die Verformung dünner Bleche zu minimieren und die Maßgenauigkeit bei komplizierten Konstruktionen medizinischer Geräte zu gewährleisten.

Architektonische und dekorative Verwendungszwecke

- 420: Für begrenzte Anwendungen wie dauerhafte Türbeschläge und dekorative Paneele in weniger korrosiven Umgebungen.

- 304: Weit verbreitet für Verkleidungen, Geländer und Skulpturen aufgrund seiner ästhetischen Oberfläche und seiner hervorragenden Beständigkeit gegen Umweltkorrosion.

Automobil- und Haushaltsanwendungen

- 420: Ideal für verschleißfeste Komponenten wie Ventilteile und Pumpenrotoren in Fahrzeugen.

- 304: Wird häufig in Autoabgassystemen, Küchenspülen und Kochgeschirr verwendet und bietet Haltbarkeit und Korrosionsbeständigkeit zu einem erschwinglichen Preis.

Zusammenfassung und Entscheidungshilfe

Bei der Wahl zwischen nichtrostendem Stahl 420 und 304 sollten Sie die folgenden Anwendungsprioritäten berücksichtigen:

Sie können sich noch nicht zwischen Edelstahl 420 und 304 entscheiden?

Unser Team kann Ihnen bei der Auswertung von mechanischen Daten, Oberflächenbeschaffenheiten und Walzwerkherkunft helfen, um die optimale Lösung für Ihre Anwendung zu finden.

Kontaktieren Sie SANMEI für Expertenunterstützung →👉 Finden Sie mit unserem Expertenratgeber heraus, wo Sie in China am besten hochwertigen Edelstahl 304 und 420 beziehen können: Edelstahl China - 6 wichtige Beschaffungsregionen.

Abschluss

Wenn Sie nach der Lektüre dieses Artikels immer noch nicht wissen, was Sie tun sollen, und Sie fragen möchten Was ist besser: Edelstahl 304 oder 420?

Was ich sagen kann, ist:

Die Wahl zwischen rostfreiem Stahl 420 und 304 hängt von den spezifischen Anforderungen Ihrer Anwendung ab:

- Entscheiden Sie sich für 420, wenn Härte, Festigkeit und Verschleißfestigkeit entscheidend sind.

- Wählen Sie 304 für hervorragende Korrosionsbeständigkeit, Verformbarkeit und Schweißbarkeit, insbesondere in feuchten oder korrosiven Umgebungen.

Wenn Sie die Stärken und Grenzen der einzelnen Materialien kennen, können Sie eine fundierte Entscheidung treffen, die sowohl die Leistung als auch die Kosteneffizienz optimiert.

Partner werden SANMEI für Ihre Projekte mit Edelstahl 420 und 304

Ob Sie nun die Beschaffung dauerhafte Härte von 420 oder die überlegene Korrosionsbeständigkeit von 304, SANMEI liefert präzisionsgefertigten Edelstahl mit Rückverfolgbarkeit ab Werk, kundenspezifischen Oberflächen und zuverlässigem Exportsupport.

Kontaktieren Sie unser Team →

Ich baue eine Außenküche aus Blöcken. Die Blöcke sind 4" x 8" x 12". Ich werde Stahl verwenden, um Öffnungen für Spüle, Türen und Kühlschrank zu überbrücken. Keine Öffnung wird größer als 40" sein. Ich klebe auch Block. Normalerweise verwende ich 1/4" Stahl, aber ich mache mir Sorgen wegen des Salzwassers, da das Projekt in Key West liegt. Ist rostfreier Stahl also genauso stark?

Hallo! Jeffrey!Ihr Projekt für eine Außenküche klingt großartig! Wenn es um Salzwasser in Key West geht, ist Edelstahl eine viel bessere Wahl als normaler Stahl, da er sehr korrosionsbeständig ist. 1/4"-Stahl ist zwar stabil, aber Edelstahl (z. B. der Güteklasse 304 oder 316) ist haltbarer und hält der rauen Küstenumgebung viel besser stand, sodass Ihre Konstruktion länger stabil und intakt bleibt. Achten Sie darauf, dass Sie rostfreien Edelstahl (316) verwenden, um eine maximale Korrosionsbeständigkeit in Salzwassergebieten zu gewährleisten. Wenn Sie weitere Fragen zu den zu verwendenden Stahlsorten haben, wenden Sie sich bitte an uns!