Stainless Steel Structural Steel: What Engineers Often Miss

From a Real Engineers' Forum Discussion to Practical Certainty in Stainless Steel Structures

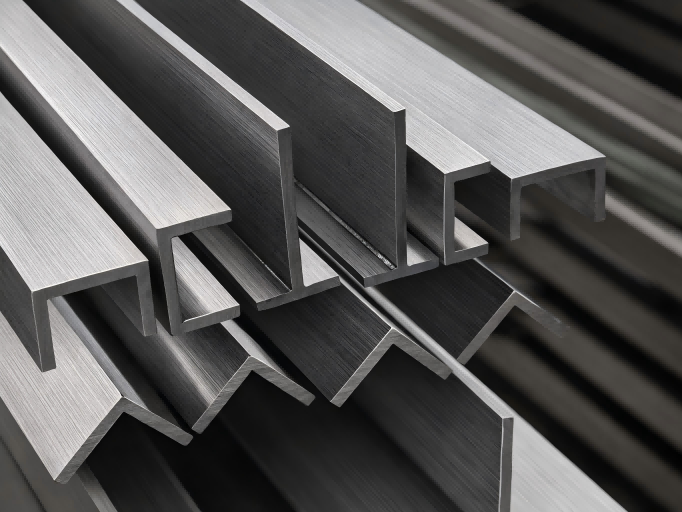

Stainless steel structural steel is used when corrosion resistance and long-term durability become part of the structural design itself, not just a protective detail.

This article explains what engineers often miss when stainless steel is used as a load-bearing material—beyond grades and design codes—based on real project experience.

What Is Structural Steel and What Is Stainless Steel Structural Steel?

Structural steel generally refers to carbon steel materials used for load-bearing applications such as frames, platforms, and industrial structures, where strength, cost efficiency, and established design codes are the main priorities.

Stainless steel structural steel refers to stainless steel used as load-bearing structural members, rather than as surface or decorative material.

It is typically selected when corrosion resistance, wash-down conditions, or hygienic requirements become governing design factors.

In these applications, stainless steel is formed into beams, columns, angles, channels, and hollow structural sections that actively participate in load bearing.

Because stainless steel exists in multiple crystal structures (austenitic, ferritic, martensitic, duplex), its structural behavior and fabrication response vary significantly.

For this reason, stainless steel for structural applications requires greater material, fabrication, and delivery control than conventional structural steel.

A Real Question Raised on an Engineers’ Forum

On Eng-Tips, a long-standing online forum used by structural engineers, one particular discussion captured a very common but often unspoken challenge.

The engineer who raised the question was not inexperienced.

He was comfortable with structural calculations and was not concerned about load capacity.

His objective was clear: to solve a corrosion problem, not to increase strength.

His concern was stated plainly:

''A previous project used carbon steel with protective coatings, but corrosion still occurred. This time, I want to use stainless steel directly. I am revising UFGS 05 50 13 and 05 50 14 and have reviewed the AISC stainless steel design guide. However, I am unsure how to specify stainless steel grades for structural shapes, tubing, plates, bolts, and anchor components in a way that will not cause problems later.

Many responses followed, but none provided a definitive answer.

Some mentioned that 304 or 316 stainless steel structural steel is commonly used.

Others cautioned against directly substituting stainless steel for carbon steel.

Some referenced the use of duplex structural stainless steel in Europe.

Others emphasized the risks associated with fasteners.

The discussion was professional, yet inconclusive.

Is This Really a Lack of Material Knowledge?

At first glance, the question appears to be about material selection. In reality, the engineer's uncertainty was not about material names.

He already knew:

- A stainless steel structure was the right direction

- Multiple stainless steel structural products are permitted by design codes

- From a calculation standpoint, these options were acceptable

What he could not confirm was something more fundamental:

Would the stainless steel structural steel specified in the drawings and specifications remain the same structure after procurement, fabrication, inspection, and delivery?

This is precisely why the forum discussion could not reach a clear conclusion.

Why Stainless Steel Structural Steel Cannot Be Confirmed by Engineers Alone

In practice, engineers often play two roles simultaneously:

- Technical decision-maker

- Driver of procurement or purchasing decisions

However, many factors that determine whether stainless steel structural members truly meet design assumptions do not occur during the design phase. They occur during:

- Raw material supply

- Thickness and tolerance control

- Stainless steel structure fabrication

- Selection of third-party inspection methods

These issues rarely appear in calculation reports, yet they directly determine project outcomes.

What Engineers Actually Need: Certainty

In stainless structural steel projects, certainty does not mean choosing a higher-grade alloy.

Real certainty comes from three conditions:

Selecting a "better" material grade based on nominal specifications

Material reliability, geometric accuracy, and fabrication integrity

This is where engineering-driven stainless steel profile suppliers become critical.

How We Secure Certainty from the Supply Side

In stainless steel structural steel projects, the greatest risk is often not selecting the wrong grade, but accepting material that merely meets minimum standards.

From the raw material stage, we focus on:

- Traceable melt batches

- Chemical compositions that remain within stable, conservative ranges

- Avoiding "borderline-compliant" chemistry driven by cost pressure

This ensures that stainless steel structural products behave as assumed in engineering design.

Different countries interpret thickness tolerance differently. In some systems, a ±5% deviation is considered acceptable.

In stainless steel structural sections, however, thickness is not a cosmetic parameter—it is a load-bearing variable.

Therefore:

- When a design specifies 3.0 mm

- We treat it as the structural assumption, not a nominal label

- Within allowable tolerances, actual thickness is controlled toward the engineering target, not toward the lower limit

This prevents stainless steel hollow structural sections and other members from compromising design assumptions at delivery.

Many failures are not caused by incorrect material selection, but by fabrication practices during stainless steel structure fabrication.

- Welding affects residual stress and geometric accuracy

- Bending marks can become fatigue initiation points

- High-requirement projects use controlled processes and coatings to minimize surface disruption

- Laser marking prevents mis-installation and part confusion

These details determine whether stainless steel structural shapes remain what the engineer originally designed.

In stainless steel structural steel projects, third-party inspection is often treated as the final safeguard. However, not all inspection methods are suitable for structural components.

In one stainless steel column project, a third-party inspector recommended ultrasonic testing to assess column quality. While this appeared professional, it was not structurally meaningful.

The reason is simple:

- Ultrasonic testing is intended for internal defects or weld inspection

- Structural columns are governed by section geometry, thickness, and dimensional integrity

- There is no established industry practice that evaluates column performance using ultrasonic testing alone.

Our role is not to replace third-party inspectors, but to help engineers clarify: What must be verified from a structural standpoint, which inspection methods are meaningful, and which methods are formally acceptable but structurally irrelevant.

Returning to the Forum Question

The reason the forum discussion never reached a conclusion is not because stainless steel structural steel is too complex.

It is because this responsibility cannot be carried by engineers alone.

In stainless steel structures:

- Design determines whether a structure is theoretically valid

- Material supply, fabrication, and inspection determine whether it remains valid in reality

Conclusion

In stainless steel structural engineering, engineers are not seeking the “best” material.

They are seeking a result that does not betray the original design assumptions from specification through delivery.

If you are preparing a stainless steel structural project, confirming these issues before placing an order is far more important than any corrective action afterward. If needed, discuss these points with an engineering-driven stainless steel supplier early in the project.