Get Your FREE Access: China’s #1 Steel Mill Dossier

Buyer-Oriented: Match mills by grade/finish/width-thickness/application

BAOWUTsingshanLiscoTisco

Gold-toned Finishes:

Rose Gold (warm & soft), Titanium Gold (futuristic & bright), Champagne Gold (elegant & subtle)

Black-toned finishes:

Matte Black, Mirror Black, Black Titanium Finishes

Copper-toned Finishes

Bronze-toned Finishes

Hairline Finish

Mirror Polishing

Vibrating Finish

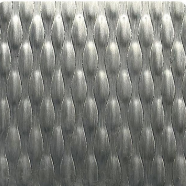

Stamped Patterns

3D Laser Engraving

NO.4 Brushed Finish

Blasting / Sandblasted

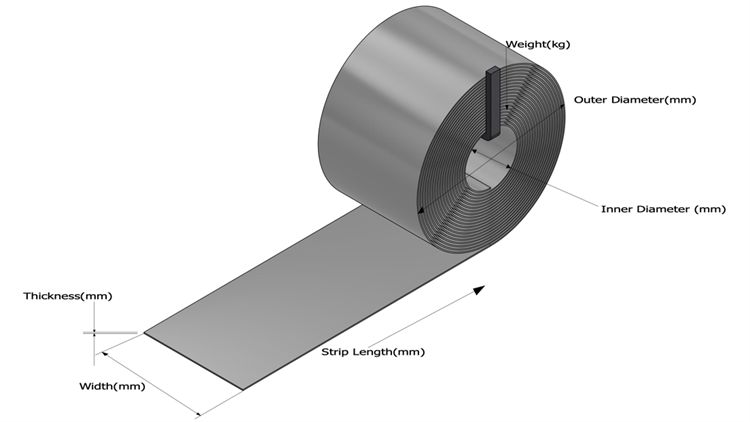

| Grade | Origin Mill | Width * Length(mm) | Thickness(mm) | Mill finish |

| 201 | Hongwang, Lisco | 1000 mm * 2000 mm(3'4" * 6'6") 1219 mm * 2438 mm(4' * 8') 1219 mm * 3048 mm(4' * 10') 1500 mm * 3000 mm (4'11" * 9'10") | 0.3-3.0 | 2B |

| 304L | Yongjin, Jisco, Posco Pzss, Tisco, Lisco | |||

| 316 | Posco Pzss, Tisco | |||

| 316L | Posco Pzss, Tisco | |||

| 304 | Yongjin, Jisco, Posco Pzss, Tisco, Lisco | 1000 * 2000 mm (3'4" * 6'6") 1219 * 2438/3048 mm mm(4' * 8'/10') 1250 * 2000/2438/3048/3000 mm (4'1" * 6'6"/8'/10'/ 9'10") 1500 * 3000 mm(4'11" * 9'10") | ||

| 430 | Jisco, Krupp |

When choosing to turn laminated stainless steel colorful, it is advisable to consider using a color overlay film as an alternative, which is flexible and cost-effective in achieving the desired color effect. While PVD coating is a high-quality surface treatment option, it is not the only choice available. With simpler application processes, overlay films can provide good visual appeal and protection. Ensure that the selected film has good wear resistance and weather resistance to suit the intended use environment. It is also recommended to conduct small-scale tests before large-scale application to ensure that the color and effect of the chosen material meet expectations.

We are committed to giving our customers the best and highest quality service to ensure our customers' satisfaction.

Customer feedback is the most authentic reflection of a company's quality.

"I've worked with Mrs Paige on numerous deals for our respective companies. At the time, I found her to be one of the most open and passionate people. Her dealing is flawless, with great coordination and problem-solving skills. You can always rely on her to come through for you and give you the best support. I can confidently say i gained a good friend and look forward to continued cooperation in the future."

"Mrs.Paige is a long time business partner, supplying me many diversified products, she has the capacity to supply any product namely finished product, raw materials, machinery, spare parts & also packing materials. She always maintains quality, price and punctuality in full filling orders. She is a good friend with whom you could confidently move forward for the betterment of any business. I wish her good luck."

Certified by prestigious institutions and committed to adhering to international standards in every aspect.

View more technical references from Sanmei Metal regarding stainless steel coils and stainless steel sheets.

Headquarters:

Creating Center, No.142, Yuhe Road, Lecong Town, Shunde District, Foshan City, Guangdong Province, China. 528315

Factory: Liyuan Logistics City, Chencun Town, Shunde District, Foshan City, Guangdong Province, China. 528313

Australia Local Support Base: (Yatala, QLD) – Coming 2026