Get Your FREE Access: China’s #1 Steel Mill Dossier

Buyer-Oriented: Match mills by grade/finish/width-thickness/application

BAOWUTsingshanLiscoTisco

Stainless steel profiles supplied for fabrication and installation, organized and delivered as project-based packages.

Designed for projects where section consistency, tolerance control, and delivery coordination are critical.

We supply stainless steel profiles to project drawings and defined requirements, covering commonly used sections such as:

Stainless steel angles

Stainless steel channels

Stainless steel flat bars

Stainless steel square bars

Stainless steel tubes and hollow sections

Profiles are supplied to project drawings or profile schedules, with dimensions defined by the design — not limited to standard stock sizes.

For each project, supply is organized at project level, with focus on:

Coordinated profile selection across the full scope

Section size and tolerance aligned with fabrication requirements

Batch-level material control and traceability

Identification and packing planned around installation sequence

This ensures profiles are delivered ready for fabrication and installation, without on-site rework.

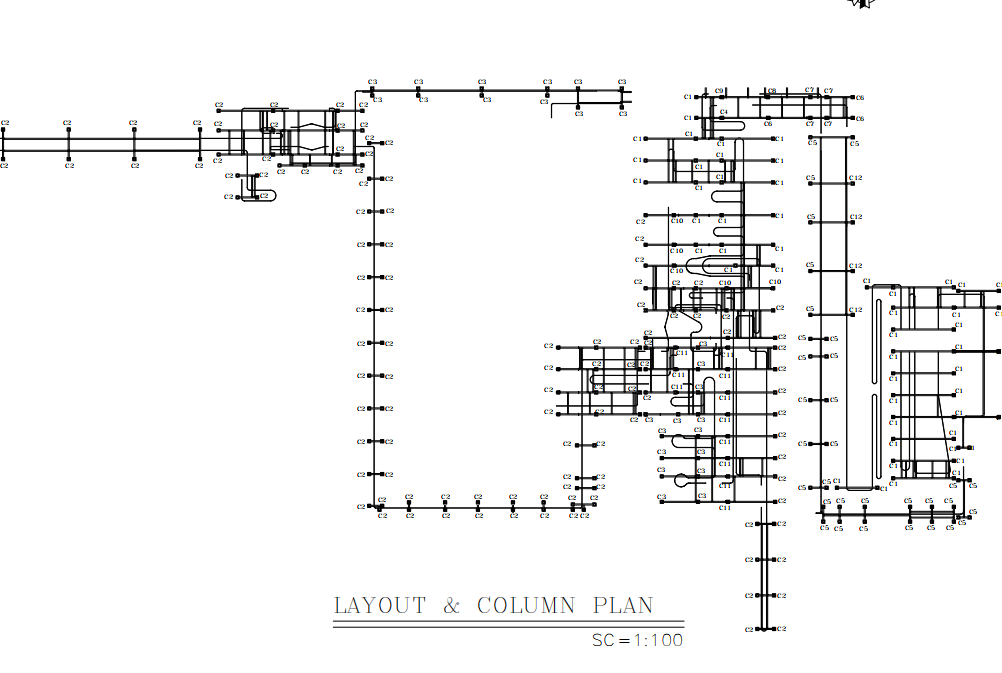

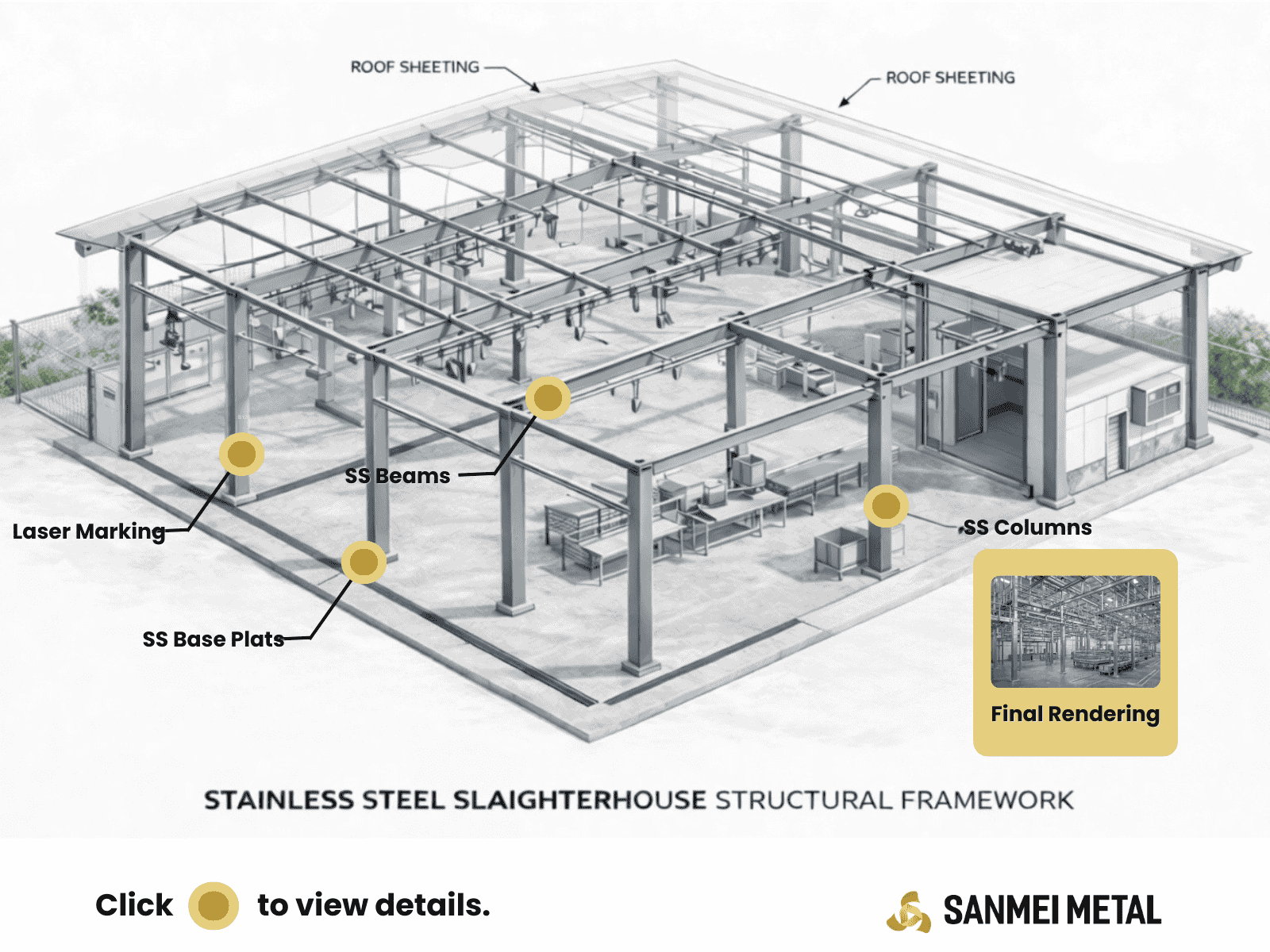

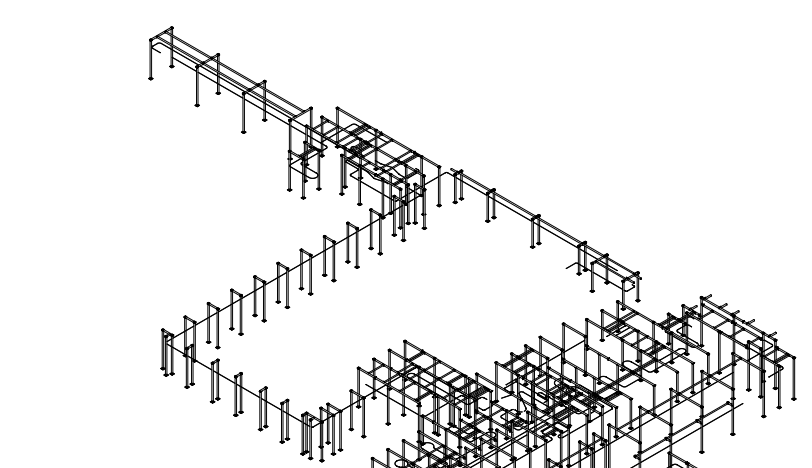

This project involves a 304 stainless steel weighing structure designed for slaughterhouse environments with high humidity and strict hygiene requirements.

The entire system is fabricated from stainless steel square tubes.

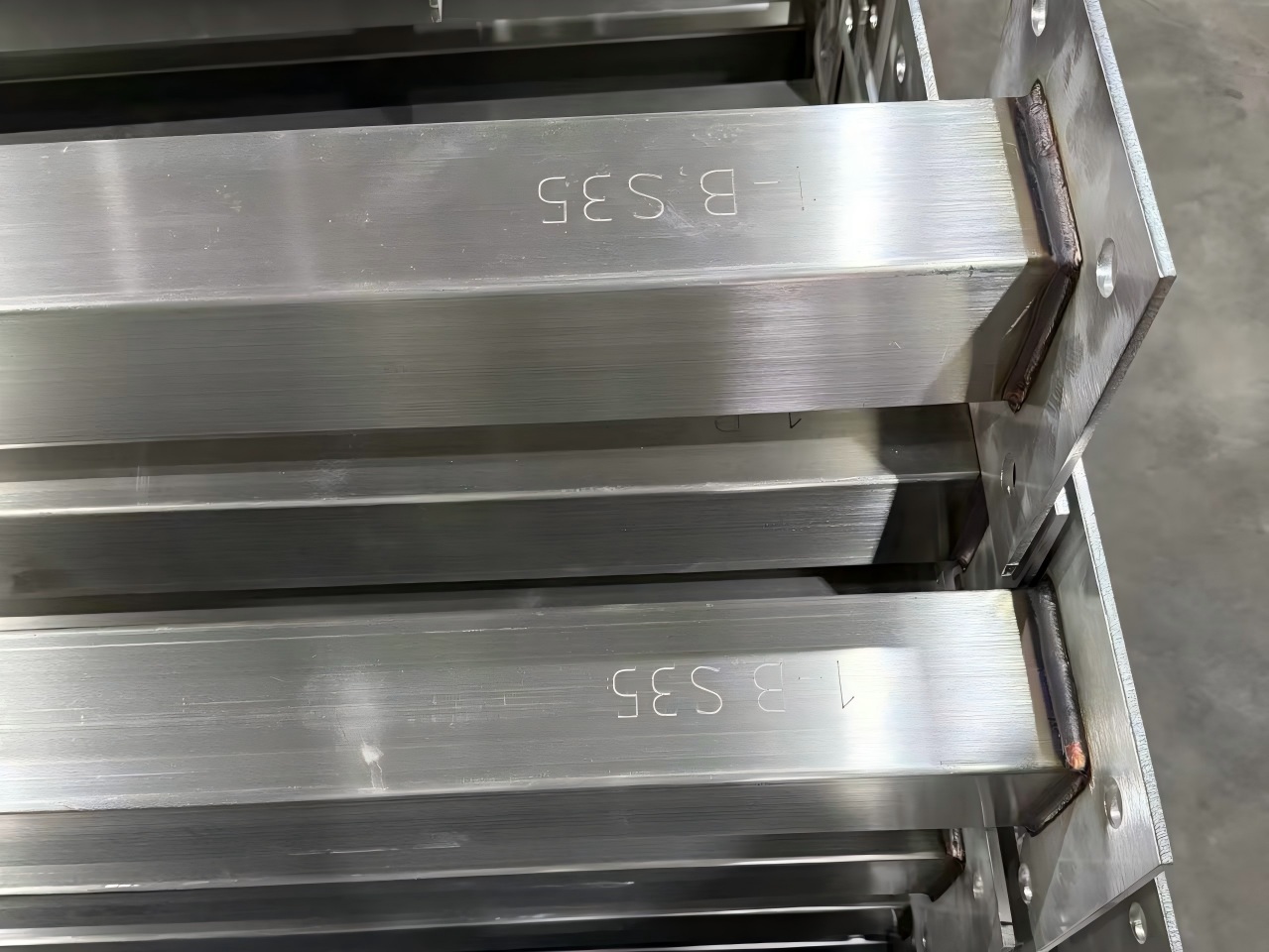

For easier on-site identification and installation, laser-marked numbering is applied to all major structural components.

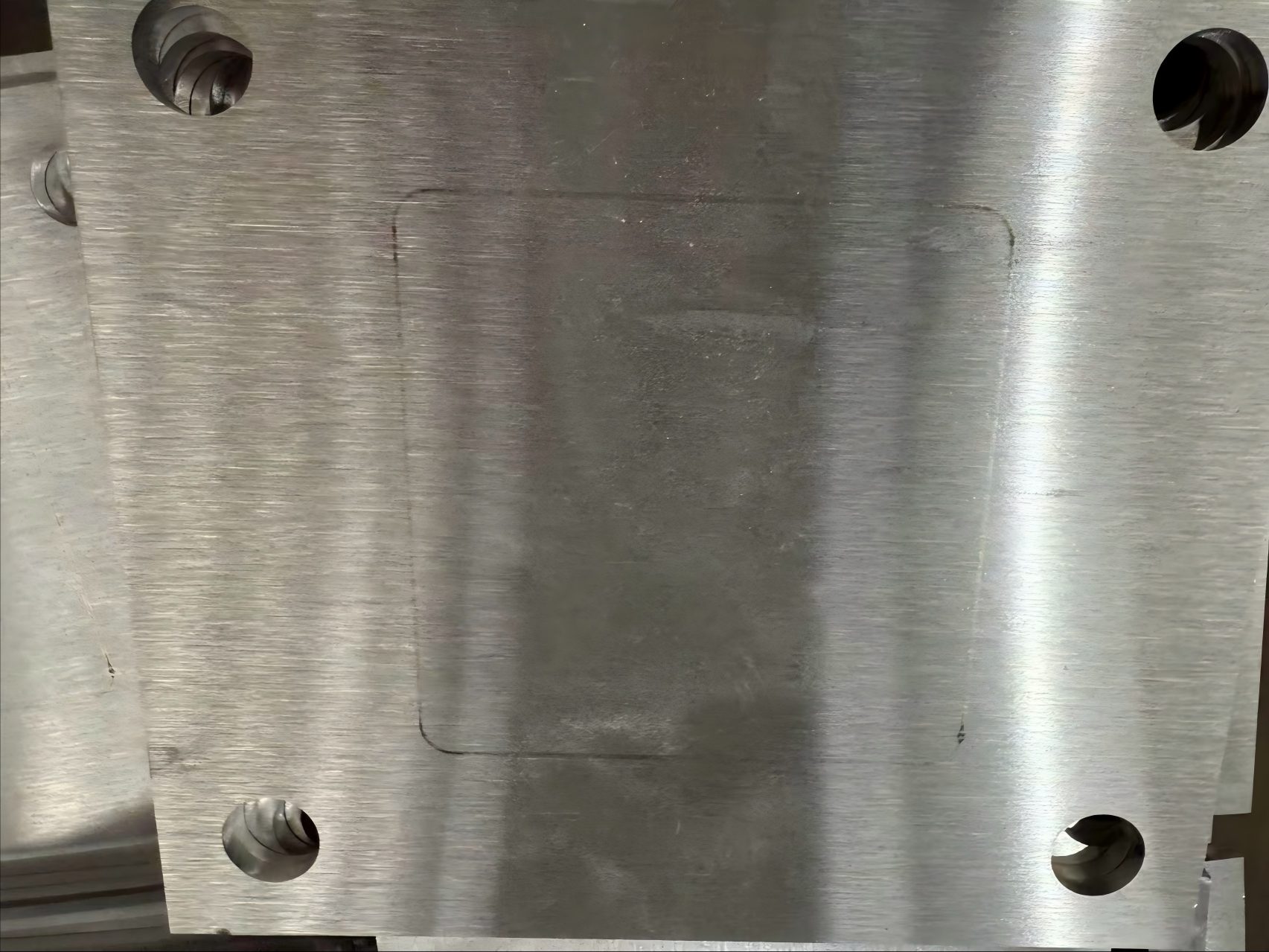

All base plates are perforated in advance, with hole positions reserved for accurate and efficient on-site installation.

The columns are fabricated from square tubes formed from 304 stainless steel plates.

A stainless steel base plate is welded at the bottom of each column, with pre-drilled holes reserved for installation and anchoring.

The beams are also made from 304 stainless steel square tubes.

Unlike the columns, stainless steel plates are welded both at the top and bottom of each beam to facilitate structural connection and installation.

All connection plates are pre-drilled according to the project drawings.

Laser marking is used to permanently identify each major component, improving installation accuracy and long-term traceability.

Provide drawings or a profile schedule to define the project scope.

Confirm grade, finish, section size, length, quantity, and tolerance.

Our profile supply is supported by fabrication partners with recognized manufacturing and quality certifications.

This ensures section accuracy, processing consistency, and documentation readiness required for project-based profile delivery.

If your project involves multiple stainless steel profiles and requires consistency in grade, finish, and section accuracy, we’re ready to support.

Share your drawings or profile list, and we’ll help confirm specifications and supply readiness before production.

Headquarters:

Creating Center, No.142, Yuhe Road, Lecong Town, Shunde District, Foshan City, Guangdong Province, China. 528315

Factory: Liyuan Logistics City, Chencun Town, Shunde District, Foshan City, Guangdong Province, China. 528313

Australia Local Support Base: (Yatala, QLD) – Coming 2026