Get Your FREE Access: China’s #1 Steel Mill Dossier

Buyer-Oriented: Match mills by grade/finish/width-thickness/application

BAOWUTsingshanLiscoTisco

Stainless steel structural steel is not processed in isolation.

In structural applications, material behavior and fabrication execution together determine whether a project works as intended.

We provide fabrication services for stainless steel structural steel, supporting drawing-based projects where accuracy, feasibility, and execution control matter.

This service supports projects where stainless steel profiles are fabricated based on approved drawings, and where section geometry, connections, and tolerances directly affect installation and service performance.

It is commonly used when fabrication decisions cannot be separated from structural intent.

We fabricate stainless steel structural steel profiles and sections commonly used in structural applications, including beams, channels, angles, flat bars, bars, and hollow structural sections.

Our fabrication services focus on preparing stainless steel structural steel for project execution, not standalone job-shop work. All services are provided in coordination with material supply, ensuring that processing methods match material grade, section size, and project requirements.

We understand how different grades, section sizes, and material conditions behave during processing.

This allows us to determine which stainless steel is suitable for your structural application, and how it should be fabricated in practice.

Engineering input is applied only where it improves fabrication accuracy and execution.

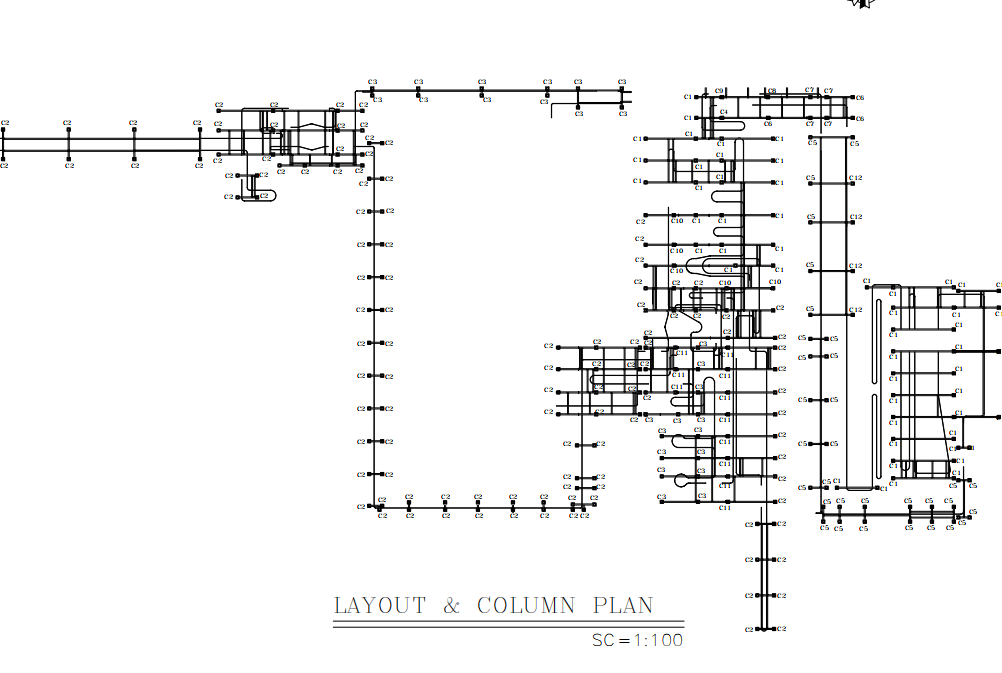

With experience from 100+ structural steel design projects, we review section layout, connection details, and fabrication approach before production. Identifying constructability issues early.

Stainless steel structural steel fabrication for industrial facilities, processing plants, and corrosive or hygienic environments.

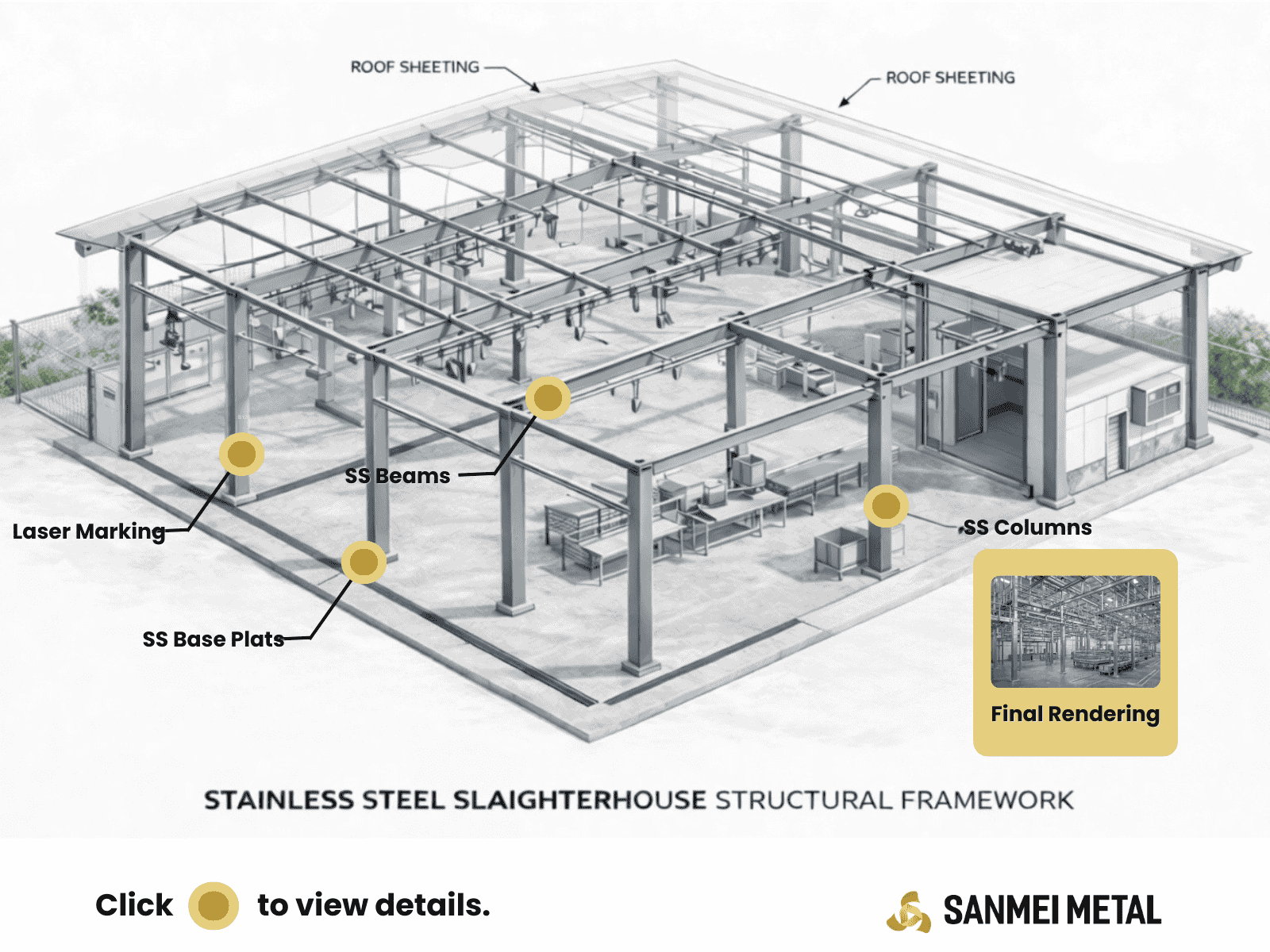

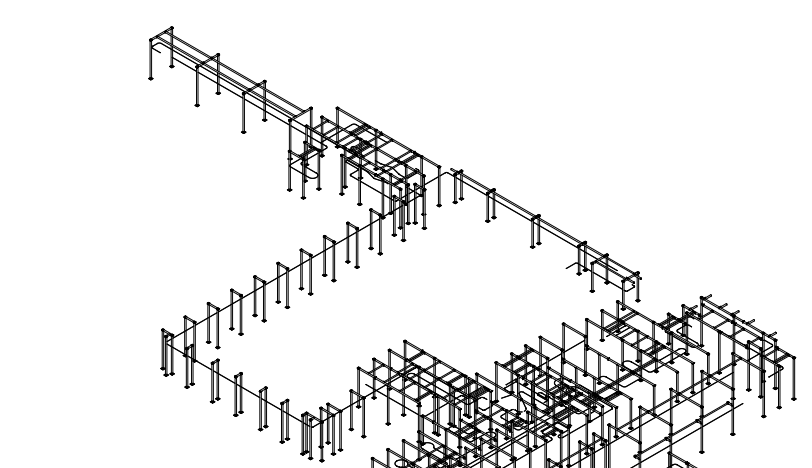

This project involves a 304 stainless steel weighing structure designed for slaughterhouse environments with high humidity and strict hygiene requirements.

The entire system is fabricated from stainless steel square tubes.

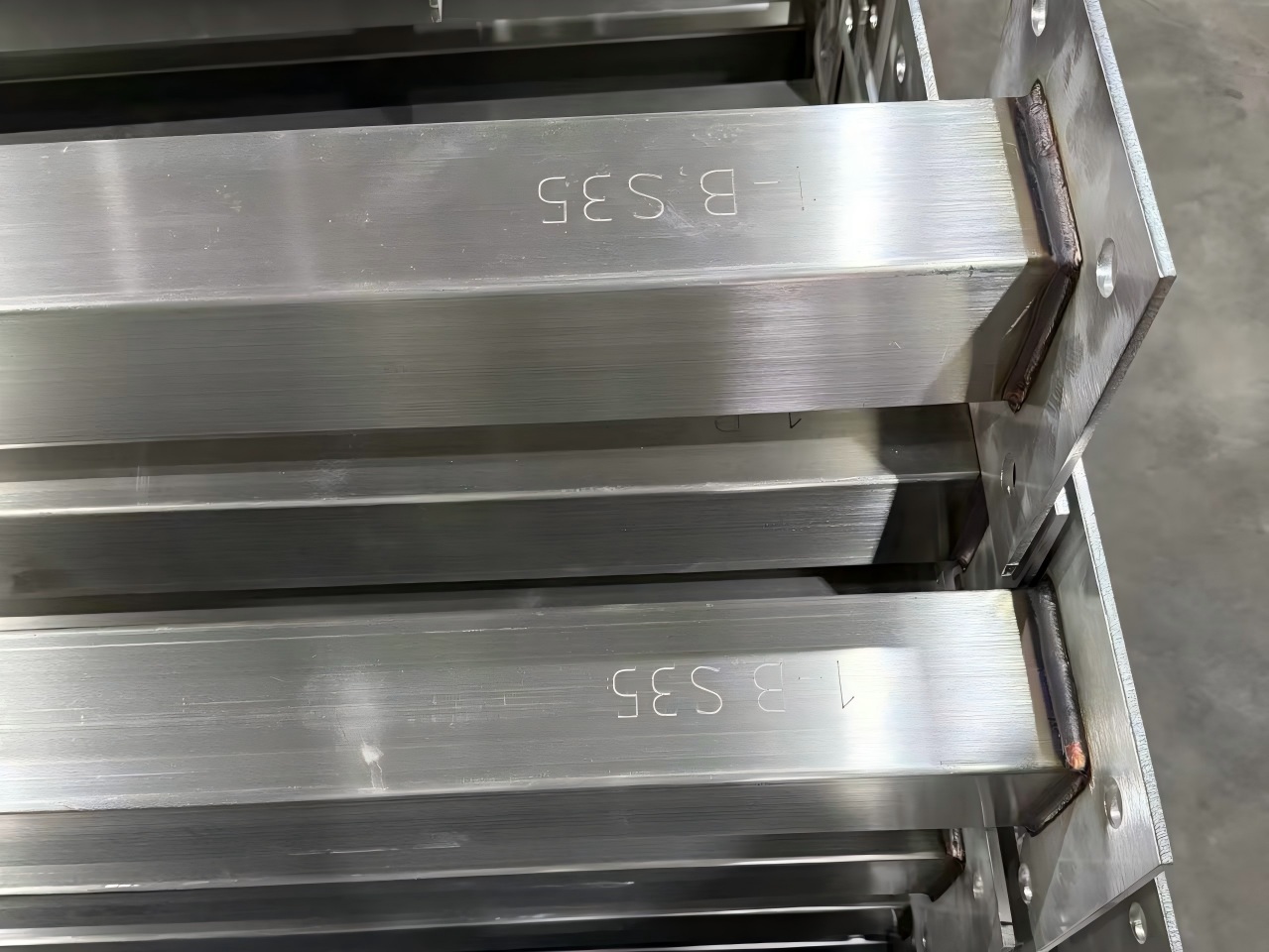

For easier on-site identification and installation, laser-marked numbering is applied to all major structural components.

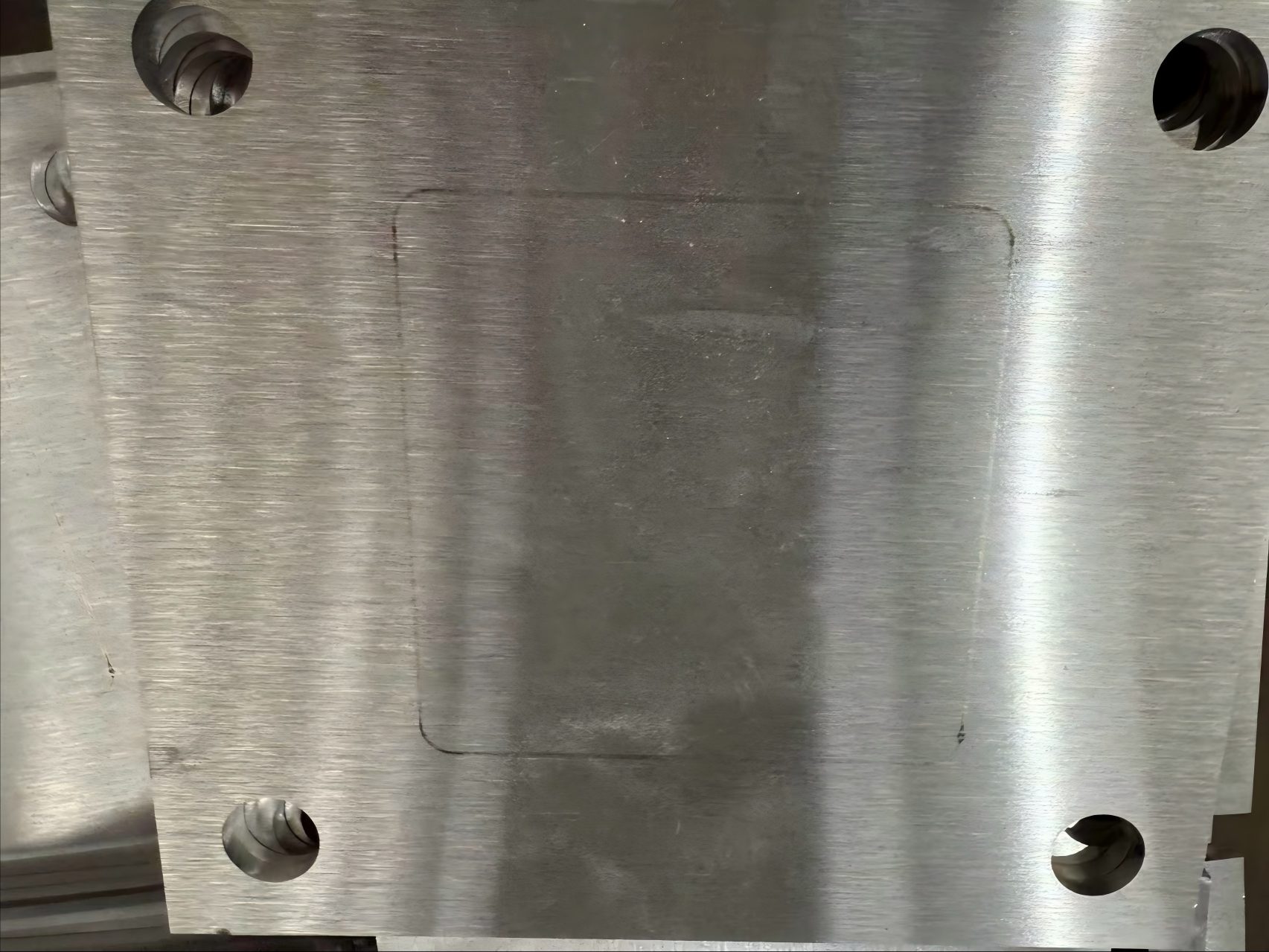

All base plates are perforated in advance, with hole positions reserved for accurate and efficient on-site installation.

The columns are fabricated from square tubes formed from 304 stainless steel plates.

A stainless steel base plate is welded at the bottom of each column, with pre-drilled holes reserved for installation and anchoring.

The beams are also made from 304 stainless steel square tubes.

Unlike the columns, stainless steel plates are welded both at the top and bottom of each beam to facilitate structural connection and installation.

All connection plates are pre-drilled according to the project drawings.

Laser marking is used to permanently identify each major component, improving installation accuracy and long-term traceability.

Provide drawings or a profile schedule to define the project scope.

Beyond confirming basic specifications—grade, finish, section size, length, quantity, and tolerance—we apply material expertise to recommend suitable grades aligned with the actual application, service environment, and project constraints.

Our engineers review and detail drawings to ensure profiles are fabrication- and installation-ready.

Price and delivery schedule are confirmed based on the approved scope.

Production begins once the order and specifications are finalized.

Our profile supply is supported by fabrication partners with recognized manufacturing and quality certifications.

This ensures section accuracy, processing consistency, and documentation readiness required for project-based profile delivery.

Headquarters:

Creating Center, No.142, Yuhe Road, Lecong Town, Shunde District, Foshan City, Guangdong Province, China. 528315

Factory: Liyuan Logistics City, Chencun Town, Shunde District, Foshan City, Guangdong Province, China. 528313

Australia Local Support Base: (Yatala, QLD) – Coming 2026