Stainless Steel 420 vs 304: A Comprehensive Material Guide

Choosing between stainless steel 420 and 304 largely depends on the specific needs of your application. Both grades have distinct properties that make them suitable for various industries. However, understanding their differences is crucial for selecting the optimal material. This article provides a detailed comparison, highlighting key attributes, applications, and recent research insights.

Curious how 420 compares to its variants 420J1 and 420J2?

Explore the complete guide: Guide to Stainless Steel 420: J1, J2, and Beyond →

Key Properties of Stainless Steel 420 and 304

When comparing stainless steel 420 and 304, it is essential to understand their material characteristics and performance differences. Below is a table summarizing their key properties:

For detailed specifications and mill-sourced materials, visit our product pages:

Stainless Steel 420

High hardness and excellent edge retention — ideal for cutting tools, knives, and industrial components.

Explore 420 →Stainless Steel 304

Superior corrosion and heat resistance — widely used in kitchen equipment, architecture, and chemical industries.

Explore 304 →🔍 Stainless Steel Knowledge Corner

You might notice that the hardness units used for 304 and 420 stainless steel differ. Let’s take a quick look at why and what each unit means.

- HRC (Rockwell C): Used for harder materials. It applies a diamond cone or steel ball to measure indentation depth — typically used for tool and hardened steels.

- HV (Vickers): Uses a diamond pyramid to measure indentation; best for thinner sheets or softer metals.

- HB (Brinell): Applies a large steel ball to the surface, suitable for rough or uneven materials.

While HRC and HV are not directly comparable, a rough conversion can be made:

- 50 HRC ≈ 500 HV — Stainless Steel 420 shows higher hardness.

- 300 HV ≈ 30 HRC — Stainless Steel 304 is significantly softer.

Need material testing data or sample hardness verification?

Contact SANMEI’s technical team

for certified mill reports and cutting samples.

In-Depth Comparison of 420 and 304

Corrosion Resistance

304 stainless steel offers significantly better corrosion resistance than 420. It excels in wet and salty environments, while 420 is more suitable for dry or mildly corrosive conditions. Studies show that chloride ions accelerate pitting in 304, while they have less impact on 420 in dry environments. 304’s resistance to rust in marine and industrial settings is far superior to that of 420.

Hardness

420 achieves higher hardness (up to 50 HRC) after heat treatment, making it ideal for wear-resistant applications. In contrast, 304 prioritizes toughness and ductility. The increased hardness of 420 is especially useful for cutting tools and abrasion-resistant components.

Heat Resistance

304 can withstand continuous exposure up to 870°C, outperforming 420, which is limited to 650°C. Heat treatment enhances 420’s abrasion resistance but can reduce its machinability and weldability.

Machinability and Weldability

304 is easier to machine and weld, requiring no special post-weld treatments. In contrast, 420 requires preheating and post-weld heat treatments, and its machinability decreases as its hardness increases. Recent advancements in laser welding technologies have improved deformation control in thin stainless steel plates, benefiting 304 by ensuring minimal thermal distortion and precise dimensional control.

Need High Hardness & Durability?

Inquire for Stainless Steel 420 — ideal for blades, tools, and wear-resistant parts.

Get a 420 Quote →Need Corrosion Resistance?

Inquire for Stainless Steel 304 — perfect for kitchen, chemical, and architectural uses.

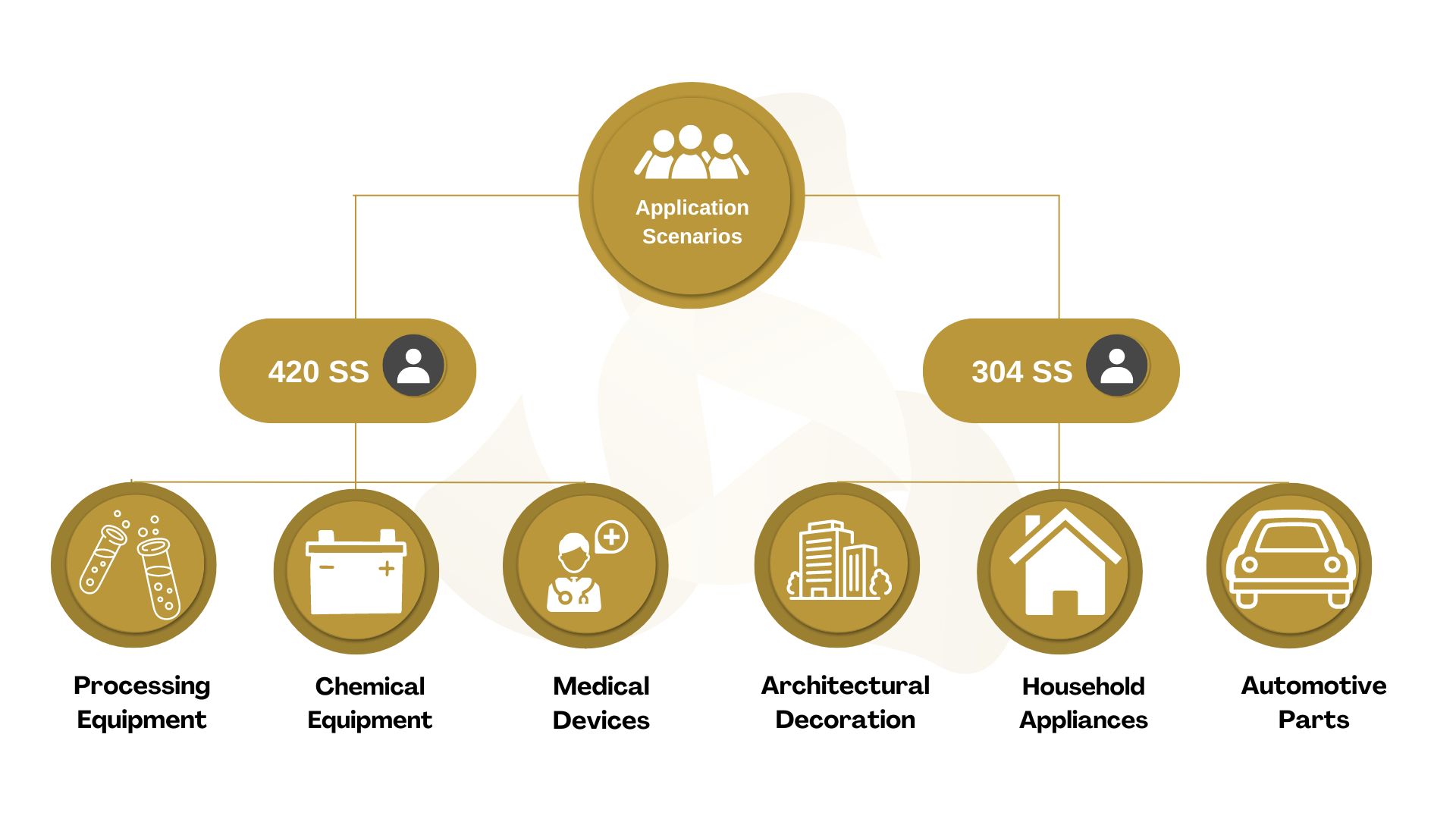

Get a 304 Quote →Application-Specific Comparison

Understanding how each grade performs in real-world applications is key to making an informed decision. Below are some examples:

Food Processing Equipment

- 420: Its high hardness makes it ideal for cutting blades and other high-wear components, such as meat grinders and slicers. These applications require durability and edge retention.

- 304: Its superior corrosion resistance makes it perfect for acidic or salty environments, such as brewing tanks, milk pasteurizers, and wine fermentation vats, where hygiene and longevity are essential.

Studies show that 304 excels in chloride-rich environments, a common condition in food and beverage industries.

Not sure whether your 420 or 304 stainless steel is truly food-grade?

Read our full sourcing guide: How to Source Real Food-Grade Stainless Steel →

Chemical Equipment

- 420: Suitable for handling mild acids and alkalis, often used in chemical mixers and pump shafts where moderate corrosion resistance is sufficient.

- 304: Performs excellently in more aggressive chemical environments, such as in storage tanks and pipes for acidic or saline solutions.

Research highlights that sulfate ions and other chemicals impact the pitting resistance of stainless steels, emphasizing 304’s superior performance in highly corrosive conditions compared to 420.

Looking for verified suppliers or mills for 304 and 420 stainless steel?

Explore China’s top production hubs in our article Top Stainless Steel Manufacturers in China →

Medical Devices

- 420: Its hardness and corrosion resistance make it ideal for surgical instruments, such as scalpels and forceps, requiring precision and durability.

- 304: Its ease of sterilization and superior corrosion resistance make it perfect for implantable devices, hospital beds, and surgical trays.

Advancements in laser welding have proven beneficial in minimizing deformation in thin plates, ensuring dimensional accuracy in intricate medical device designs.

Architectural and Decorative Uses

- 420: Used in limited applications such as durable door hardware and decorative panels in less corrosive environments.

- 304: Widely used for cladding, railings, and sculptures due to its aesthetic finish and outstanding resistance to environmental corrosion.

Automotive and Household Applications

- 420: Ideal for wear-resistant components like valve parts and pump rotors in vehicles.

- 304: Commonly found in car exhaust systems, kitchen sinks, and cookware, offering durability and corrosion resistance at an affordable cost.

Summary and Decision Guide

When choosing between stainless steel 420 and 304, consider the following application priorities:

Still Deciding Between 420 and 304 Stainless Steel?

Our team can help you evaluate mechanical data, surface finishes, and mill origin to match your exact application.

Contact SANMEI for Expert Support →👉 Find out the best places in China to source quality 304 and 420 stainless steel with our expert guide: Stainless Steel China — 6 Must-Know Sourcing Regions.

Conclusion

If you still don't understand after reading this article, and want to ask which is better, 304 or 420 stainless steel?

What I can say is:

Choosing between stainless steel 420 and 304 depends on the specific needs of your application:

- Opt for 420 when hardness, strength, and wear resistance are essential.

- Choose 304 for superior corrosion resistance, formability, and weldability, especially in moist or corrosive environments.

Understanding the strengths and limitations of each material allows you to make an informed decision that optimizes both performance and cost-efficiency.

Partner with SANMEI for Your 420 & 304 Stainless Steel Projects

Whether you’re sourcing the durable hardness of 420 or the superior corrosion resistance of 304, SANMEI delivers precision-graded stainless steel with mill traceability, custom finishes, and reliable export support.

Contact Our Team →

I'm building an outdoor kitchen out of block. The block are 4" x 8" x12". I will use steel to bridge opening for sink, doors and fridge. No opening will be more than 40". I also glue block. I normally use 1/4" steel but I'm concerned about salt water as project is in key west. So is stainless just as strong?

Hi! Jeffrey!Your outdoor kitchen project sounds great! When considering saltwater exposure in Key West, stainless steel is a much better option than regular steel, as it is highly resistant to corrosion. While 1/4" steel is strong, stainless steel (such as 304 or 316 grade) offers enhanced durability and will withstand the harsh coastal environment much better, ensuring your structure remains stable and intact for longer. Just make sure to use marine-grade stainless steel (316) for maximum corrosion resistance in saltwater areas. If you have further questions on the specific steel types to use, feel free to ask!